Machining

Filter by Process Zone:

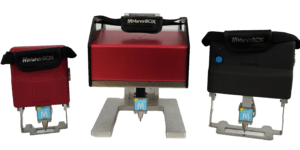

Marking Parts Is About More Than Just the Machine

MB Metal Technologies’ Sketchbook2 software greatly simplifies the process of programming the company’s benchtop, fixed-mounted, integrated, and portable dot peen marking equipment. The user sees and can easily change text and logos before marking begins.

Global Gundrilling OEM Celebrates 40 Years of Growth

Kays Engineering Inc., which makes the DeHoff, Eldorado, and TechniDrill brands of gundrilling machines, has grown from small welding and repair shop to a 60-employee leader serving customers in 30 countries across five continents.

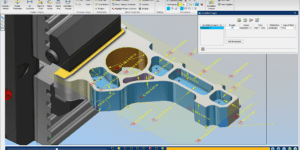

Collaboration Ensures Seamless CAD and PMI Data Exchange

Two Open Mind Technologies software products have been integrated into Tech Soft 3D’s Hoops Exchange. As a result, users can share any CAD file type without compromising product and manufacturing information (PMI) data.

Off-The-Shelf Solution for Noncircular Grinding

NUM enhances its Flexium+ CNC software by adding noncircular grinding functionality to NUMgrind. A graphical interface backed by a comprehensive library of predefined shapes simplifies production of camshafts, punches, cams, eccentric shafts, etc.

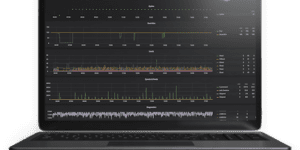

Platform Leverages High-Frequency Data to Avert Failures

MachineMetrics HF collects data at 1 kHz directly from a CNC machine’s controls without using sensors. The data can immediately be used as inputs to time-series or machine learning models to predict machine and tooling failures.

Upgraded Monitoring Software Connects Multiple Brands

Heidenhain’s StateMonitor 1.3.0 software connects CNC control and PC systems, enabling manufacturers to remotely monitor equipment performance in real-time regardless of brand without having to access the cloud.

Software Enhancements Raise the Bar for Process Simulation

CGTech incorporated hundreds of customer-requested improvements into Version 9.1 of its Vericut CNC software. Enhancements include advancements in graphics and display controls, streamlined controls, and new visibility options.

Multifunctional Machine Tool Platform

Bourn & Koch’s MT3 increases productivity and quality. The one-and-done machine can perform grinding, milling, turning, and drilling/tapping machining operations on a workpiece in one setup.

BobCAD-CAM Updates Software Program

BobCAD-CAM V33 offers more functionality than ever before. This version has 36 upgrades and enhancements affecting general CAD; BobART; general, mill, and lathe CAM; and simulation.

F-35 Fighter Jet Blasts Off with Precision Components

As a joint strike fighter (JSF) partner, Starrag Group machines help manufacture the world’s most complex military aircraft. The Droop+Rein FOGS 6-axis machining center with 300 Nm spindle rough-machines steel and titanium components using a variety of heads and performs high-speed finishing of dies.