Machining

Filter by Process Zone:

Compact, High-Precision Multitasking Machining Center

Methods Machine Tools, the exclusive U.S. importer of Nakamura-Tome multitasking turning centers, introduces the Nakamura-Tome MX-100 with multiple ‘smart’ functions that ease programming and operation. Design eliminates need for positioning fixtures and clamping devices.

Multitasking Machine Automatically Loads/Unloads Parts

The Quick Turn 250SMY with GR100 gantry robot is one example of how Mazak’s flexible Quick Turn 200/250 Series of CNC turning centers can be configured to achieve high throughput. Main turning spindle serves as a full-functioning C-axis.

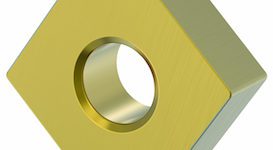

Inserts Make Hard Turning More Cost-Effective

Polycrystalline cubic boron nitride (PcBN) mini-tipped inserts are a great way to lower per-part cost when turning hardened steel components. Kennametal´s two grades of double-sided PcBN inserts increase productivity and extend tool life when machining materials up to 65 HRC.

Redesigned Machine Reinforces Company’s Brand

With its precision interface for fast tool changeover and direct drive for high-power milling of complex workpieces, Emco’s Hyperturn 45 G3 with two Turn/Mill-Assist automation options provides a flexible drilling and milling solution for a wide range of workpiece geometries and weights.

Twin-Spindle Machine Lowers Gear Manufacturing Costs

Soft- or hard-machine a bevel gear in 25 to 40 seconds with EMAG’s VL 1 Twin, a pick-up turning machine that simultaneously machines two identical bevel gears at high speed within the same machining area. Automating the loading process lowers cycle time to 4.5 seconds.

Tooling Supports More Versatile Long-Grooving

Dormer Pramet targets turning center and lathe applications with an insert, two geometries, a grade, blades, and tooling that support parting-off and grooving. Double-edged insert supports 60% capacity over the LCMF16 insert.

Multispindle Automatic Lathe With Swiss-Type Technology

DMG MORI and igus spent two years developing the Multisprint, the first machine to combine the efficiency and precision of a turning machine with the complexity of a universal turning machine.

Cut Overall Cycle Time With On-The-Fly Laser Marking Machines

Shaving every second possible from each process is a key objective for high-speed, high-volume manufacturers. Laser marking on the fly helps by recording data on a moving target in milliseconds. Pryor Marking Technology’s Alastair Morris explains.

New Line Of Dot Peen And Fiber Laser Markers

Dapra Marking Systems introduces the part-marking technology of Spanish manufacturer Datamark Systems to North America. Headlining the new offerings is a series of truly portable dot peen markers.

Time-Saving Tool Cleaning and Laser Marking Join with Robot Loader

Walter Helicheck Plus and Helicheck Pro machines from United Grinding North America use robotics to increase the speed and efficiency of cutting tool production and inspection.

Dot Peen Marking Machine Keeps Up With The Flow

SIC Marking’s extremely compact i-speed with pneumatically integrable system uses continuous vibrating dot peen technology to mark up to 10 characters per second in extremely high-speed production environments.