Machining

Filter by Process Zone:

Artificial Intelligence Powers Spindle Health Monitoring

Predictive analytics diagnose pre-failure conditions before downtime occurs. Mazak’s Spindle Health Monitoring System uses edge computing and algorithms to model a spindle’s baseline signature against which anomalies that indicate developing alignment or balance issues are readily identifiable.

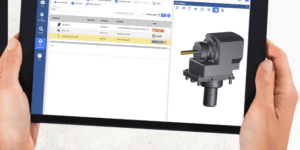

Cloud-Based Cutting Tool Configurator Saves Time and Money

MachiningCloud fast-tracks a shop’s entire workflow by providing direct access to tooling data and speed-and-feed recommendations that can be read directly into CAM and simulation programs. In addition to enabling users to quickly configure the right tool for a job, the platform provides pricing and availability.

Contract Manufacturer: Single Operator Can Double+ Output

As part of a strategy to increase uptime, enhance the accuracy of machined parts, and expand the size of parts they can produce, J&R Machine installed two DMG MORI NZX 2000 automated CNC systems at its Shawano, Wis., headquarters. A single machine operator will be able to more than double his or her current output of complex parts.

Achieve Autonomous Manufacturing with Milling Automation Solutions

Connected, customizable, safe, and space-saving describe some of the automation features coming from DMG MORI. Fifty-two automated workpiece and pallet handling solutions are hitting the market, including Robo2Go, PH Cell, WH3, and the RPS21.

Keep Working Remotely with Free Software Services ‘Til Year-End

To help their customers maintain production during the pandemic, ABB announces that as of March 27, they will offer key digital services at no charge. These services include ABB Ability Connected Services and RobotStudio, and the company is also providing complimentary virtual technical support.

Cost-Effective Tool Grinding for Re-Sharpening Sector

United Grinding focuses on the re-sharpening sector of the rotationally symmetrical tool market with its versatile Walter Helitronic Raptor. It’s the solution for shops that don’t need automatic tool support systems and automatic grinding wheel changers – but where high flexibility is required in the work area for diverse tool types.

Multiaxis Machining Gives Shops Competitive Advantage

With simultaneous 4- and 5-axis machining capabilities, the Mastercam Multiaxis add-on puts basic and advanced machining strategies into the user’s hands. A ‘near miss tolerance’ setting lets the machinist determine how close the cutter can come to the part.

Updated Centering Vice for Vertical Machining Centers

Hoffman Group’s Garant Xtric is available with a center jaw, gripper mounting holes, endutec automation interface, and four additional base lengths. The vice provides 25 kN of clamping force.

Vertical Machining Center for Small Parts

Palmgren’s 8.5-inch-by-27-inch vertical machining center (VMC) is an economical way to manufacture small parts. An automatic tool changer and 8-tool magazine make the machine suited for prototyping and short run shops.

Methods Machine Tools Introduces Its Own Line of VMCs

Methods Machine Tools is offering four 3-axis vertical machining centers (VMCs) and a 5-axis bridge-type machining center made by Taiwanese tool builder Litz Hitech. Equipped with Fanuc controls, they provide an accurate and reliable mid-range machining solution.

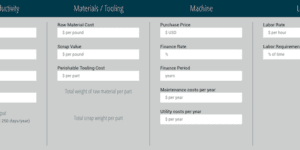

How Profitable Can You Be With Brass?

Find out using a free machine tool payback calculator created by the Copper Development Association Inc. (CDA). Visit https://highspeedmachiningbrass.com/profit/.

Vertical Machining Center Series for Large Components

Designed for large-volume production of complex structural components for the automotive and aerospace industries, the FZ/DZ 25 series of two-spindle vertical machining centers (VMCs) from Chiron Group delivers 20,000 rpm in a small footprint.