Machining

Filter by Process Zone:

Affordable, Compact Drilling and Tapping Centers

The Tongtai VTX series from Absolute Machine Tools provide speeds up to 2,362 ipm in all axes and acceleration of 1.2 g. Two types of high-speed automatic tool-changing systems are available.

Asymmetric XY Stages With Nanometer-Level Precision

ALIO introduces a positioning solution that provides customers with the exact X and Y travel ranges needed for their applications.

Compact Spot Welding Robot

FANUC’s R-2000iD/210FH Robot offers system uptime while operating in tight workspaces.

Hexagon to Acquire CAE Software Maker Romax Technology

Adding Romax’s expertise in electromechanical drivetrain design and simulation to its Manufacturing Intelligence division will, says Hexagon, enhance its Smart Factory Solutions.

Laser Line Ultra Simplifies Micro Cutting Tool Production

United Grinding’s Laser Line Ultra uses an 8-axis configuration and picosecond lasers to machine complex micro geometries in cutting tools regardless of the material’s hardness.

Servo Drive Triples Milling Rates

Equipped with servos for the X, Y, and Z axes, Tormach’s 1100MX is up to three times faster than the company’s 1100M and 770M mills. The machine delivers speeds of up to 10,000 rpm.

Type BSM and BSM-B Ball Screw for Machine Tools

Featuring high-speed performance and load capacities that exceed existing full ball standards, these new ball screws from THK America are ideal for machine tools.

Stationary Workholding Virtually Eliminates Setup Time

Accessories and adapters for SMW Autoblok’s manual APS and WPS stationary workholding systems ensure flexible clamping of nearly every geometry without interfering with machining or contours, making them ideal for 5-axis machining. Zero-point clamping reduces setup time up to 90%.

Upgraded Milling Software Suite

The latest version of hyperMILL 2020.1 CAD/CAM software from Open Mind Technologies includes 3D and 5-axis machining enhancements for complex parts as well as new automation and additive manufacturing strategies.

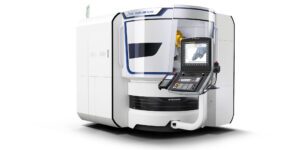

5-Axis Milling Machine Simplifies Complex Cutting Tasks

MC Machinery’s Eagle V5 can perform high-precision cuts with the X, Y, Z, B, and C axes moving simultaneously. Integrated 4/5-axis system allows X, Y, and Z travels of 21.6 in, 15.7 in, and 15.7 in, respectively.

Boring Technology for Automotive Engine Rebuilding

Kays Engineering’s 3-axis DeHoff 1036 is designed for re-boring the CAM journals of automotive engine blocks. The single-spindle CNC boring machine has a capacity of 1 in (25.4 mm) and depth of 36 in (914 mm).

Microspindle Converter Operates Two Spindles Simultaneously

IBAG North America’s space-saving converter enables two microline spindles to operate simultaneously from one drive at speeds from 5,000 rpm up to 100,000 rpm.