Machining

Filter by Process Zone:

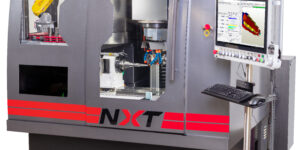

Small-Footprint Grinder with Large Work Zone

Star SU’s easily configurable NXT 5-axis grinding machine gives manufacturers the ability to run small- and large-diameter wheels to sharpen straight and spiral gash hob designs as well as disk-, shank-, and helical-type shaper cutters, Scudding cutters, and a wide range of round tools.

Increase Productivity with a Five-in-One Machine

The Elb-Schliff millGrind BL10 from Precision Surfacing Solutions (PSS): grinding, drilling, and milling in one clamping; deep grinding and, with an optional laser head, deposition welding in the other. A complete machining solution for aerospace manufacturers.

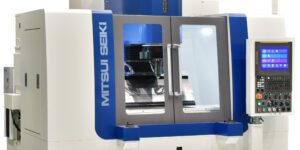

Compact Automatic Jig Grinder

Mitsui Seiki’s new-and-improved J350G grinds small- and large-diameter holes as well as multiple features using a single wheel in a continuous, automatic mode. The machine is 50% smaller than the previous model, giving manufacturers more options for shop floor usage.

Power Skiving and Gear Shaping in One Machine

A hydraulic chuck combined with a changeable back stop and slotted collet, the Mytec Hydraclamp paves the way for power skiving by enabling users to clamp different diameters and components with one hydraulic chuck.

Chamfer Cutting of Interfering Contours & Internal Gears

Apart from milling pins, there haven’t been many solutions for chamfering internal gears – a severe limitation given that roughly half the gears and shafts in a gearbox have interfering contours. Liebherr Gear Technology’s ChamferCut collision gear technology addresses this problem.

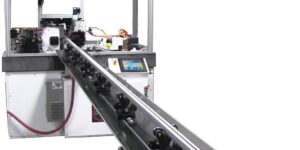

Designing a Solution for Thrufeeding Metal Tubes

Process-improvement company helps customer reduce lead times and costs by configuring an infeed/thrufeed centerless grinding machine with custom software that enabled the customer to vertically integrate.

Nine New Grinders & Sanders

Chicago Pneumatic’s CP3550 product lineup of 17 compatible finishing models allows perfect matching of applications and tools. Greater torque increases material removal rates and operator comfort while deburring, contouring, chamfering, fettling, removing seam welds, preparing surfaces, cleaning, polishing, and finishing.

Walter Acquires Melin Tool Company

A global precision tool manufacturer serving the metalworking industry, Walter anticipates that a stronger presence in the U.S. will help the company grow its product line with local market requirements and improve market support with customized tooling solutions.

Hurco Forms Preferred Partnership with BMO Automation

The BMO Automation package focuses on high-mix/high-volume production to help manufacturers deal with the skills gap and labor shortage and increase productivity of their CNC machines.

NCSIMUL Hires New Midwestern Territory Account Manager

Jim Ellingsen will work with customers using Hexagon’s manufacturing simulation solution

Welcome to the Next Decade: Metalworking in Industry 4.0

During the next ten years, more fabricators will compete with sophisticated, connected networks that apply artificial intelligence to manage data that reduces their cycle times in design to manufacturing to delivery.

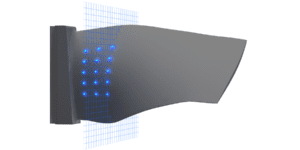

Automated Adaptive Milling

Automated adaptive blade milling from Liechti Engineering measures the workpiece in the machine and CAM software generates and optimizes a tool path that eliminates human error, optimizes productivity and ensures the highest quality result.