Machining

Filter by Process Zone:

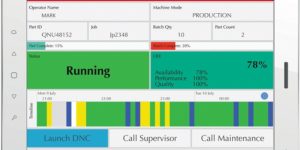

Flexible Tablet Interface for Easy Exchange of Shop Floor Information

For CNC machine tool and non-CNC asset monitoring and data collection, the Flexible Tablet Interface from FactoryWiz uses a live display dashboard to drive behavior and see quantifiable improvement in shop productivity.

Driving Towards Seamless Factory Connectivity

Excellerant connects every CNC machine tool controller, no matter the brand, so that shops of all sizes can monitor and manage each machine’s data in real-time and send that data to the company MES and/or ERP systems for more accurate forecasts and dynamic scheduling.

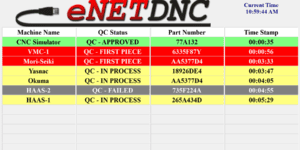

Automated Monitoring of First Piece Inspection on the Shop Floor

Working in conjunction with eNET Machine Monitoring, the eNET QC Status Dashboard from eNETDNC is locally-hosted software that increases visibility and accountability throughout the quality control operation for the first-piece inspection process.

Cybersecurity of Communications Between Controls

By passively intercepting and monitoring serial communications on industrial control networks for intrusion detection and asset management, the SerialTap cybersecurity sensor from Cynash helps shops address and solve complex security challenges that affect their legacy control systems.

Automatic Data Analysis Increases Shop Floor Efficiency and Reduces Downtime

ShopFloorConnect 6.0 OEE and Shop Floor Data Collection software from Wintriss Controls gathers production data from every machine in the factory, displays the Key Performance Indicators in real-time and produces detailed analytics, including comprehensive OEE reports in a variety of formats.

Secure Transfer of Process Data to Mobile Devices

TwinCAT IoT Communicator software and the IoT Communicator App for tablets and smartphones from Beckhoff Automation uses advanced encryption and protocol for easy mobile device integration and high-level communication security.

Sensors + Software = End-To-End Internet of Things

The Connected Data Solutions Platform from Banner Engineering allows users to easily and securely transmit and use remote data from cloud-connected devices to monitor shop productivity, predict machine maintenance requirements and make operational decisions on machine performance.

Create A Community for Sharing Metalworking Automation

Using the HKP Mobile App from Haydon Kerk Pittman, technical information and other resources on linear and rotary solutions can be easily shared among colleagues and teams for automation in metalworking, inspection and material handling applications.

Online Equipment Monitoring Drives Productivity Improvements

The CoroPlus MachiningInsights digital system from Sandvik Coromant collects data directly from a connected machine tool and input from operators, making it possible to visualize machine and tool utilization levels online through a web browser and collaborate to make improvements within the factory.

End-To-End Digitalization for the Machine Tool Business

In both the construction and utilization of machine tools, Siemens is laying the foundation for digital penetration and restructuring of complete value chains that will boost the growth and profitability of both machine builders and users alike in shops of all sizes.

What Does “Collaborative” Really Mean?

Human-robot collaboration is changing manufacturing operations by helping shops deal with competitive pressures and a lack of skilled labor, but it is not a “one size fits all” solution. Before you invest, consider the different forms of robotic collaboration and how they apply to your entire application.

Boeing Awards Fives Lund

They receive the Supplier of the Year Award in Technology.