Machining

Filter by Process Zone:

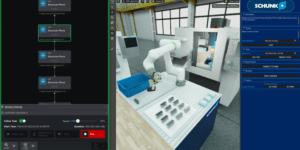

Wide Range of Robotic and Automated Systems Enhance Metal Cutting Enterprises

Machinists are breaking new ground in their performances and processes thanks to the ability to work safely alongside cobots and realize shorter load/unload times.

Renishaw Launches new Line of Industrial Automation Products

The new RCS product line solves fundamental challenges within the global industrial automation industry. It places the focus on problems associated with manual set-up, calibration, and maintenance of robots, such as operational accuracy and repeatability.

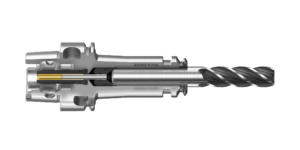

MQL Efficiency Added to powRgrip Toolholding System

The REGO-FIX standardized MQL PG collets are designed for tool shanks according to DIN 69090-3 and available for HSK-A 63 and HSK-E 40 toolholders.

Multi-Axis Force/Torque Sensors now Compatible with FANUC Robots

Seamless integration with FANUC’s Force Control Software unlocks new possibilities for ATI Industrial Automation’s robotic applications.

ANCA’s FX5 Gets a Power-boost with a new 12 kW Grinding Spindle

ANCA is celebrating the versatile FX machine platform as the 1,000th FX5 rolls out the door.

New SINAMICS S200 Servo Package is Fit for Future Manufacturing Applications

Siemens brings a new level of motion control to the stand-alone and networked machine market. This new servo package expands the SINAMICS drive offering a variety of application possibilities to the standard servo market.

Next-Generation CNC Machine Control from Okuma America Corp.

The new Okuma OSP-P500 control comes standard with dual-core computer processors which provide increased levels of machine processing power by enabling multiple processes to operate simultaneously.

Delivery in Four Days: Accelerated Anodizing and Chromate Plating for Machined Parts

From time of quote to manufacturing to shipping, Protolabs’ customers can now get custom machined parts with plating in as fast as four days.

One-Step Production with Automated Blanket Grinding Solution

ANCA’s continuous and complete tool production from longer bar stock to finished product using an automated solution saves time by eliminating extra processes or handling.

FABTECH 2023: Teach-By-Touch 7-Axis Cobots Take Over Repetitive Tasks

Productive Robotics’ Teach-By-Touch 7-axis cobots automate tasks from welding to milling and grinding, which boosts production efficiencies and reduces operating costs.

FABTECH 2023 – METALFORM, Finishing, Tube & Pipe

Hall D: METALFORM, Finishing, Tube & Pipe of FABTECH 2023, North America’s largest metal forming, fabricating, welding and finishing event.

FABTECH 2023 – Welding, Welding Automation, Robotics & Industrial Automation

Hall B: Welding, Welding Automation, Robotics & Industrial Automation of FABTECH 2023, North America’s largest metal forming, fabricating, welding and finishing event.