Machining

Filter by Process Zone:

Seco Machine Achieves ISO Recertification

They are recertified under ISO 9001:2015 for machining metal and cast urethane components.

Universal Robots Hires Former Rethink Robotics Staff

They add extensive collaborative robotics experience in engineering, product development, and customer applications.

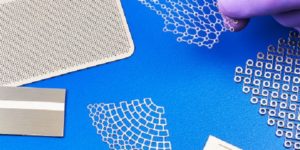

Precision Chemical Machining of Titanium Medical Implantable Parts

Chemically machined titanium parts from Photofabrication Engineering match exact OEM design requirements, including varying depths and intricate patterns, with exact part-to-part and batch-to-batch repeatability.

CNC Centerless Grinding of Higher Precision Medical Components

Using intelligent controls, the GT-610 CNC centerless grinding system from Glebar provides high horsepower, strong rigidity and superior slide positioning for grinding multiple parts per cycle on a 10 in or 12 in diameter grinding wheel.

Advanced Swiss Turning for Medical Device Manufacturing

The Traub TNL20 sliding/fixed headstock automatic lathe from INDEX adds numerous improvements to productivity, precision, and automation in medical device manufacturing.

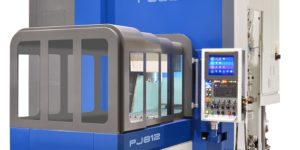

High Precision Contour Machining of Medical Components

The PJ812 Precision Profile Center from Mitsui Seiki is a three-axis CNC vertical jig mill for high precision contour machining and ultra-precise boring of medical components with critical tolerances.

High Precision Gundrilling of Bone Screws, Surgical Instruments and Other Medical Components

Using a counter-rotating workpiece headstock that greatly enhances concentricity on small parts, the UNE6 gundrilling machine from UNISIG is ideal for drilling bone screws and surgical instruments made of high strength titanium or surgical-grade stainless steel.

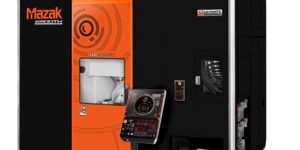

Micro-Precise High Speed Machining of Medical and Dental Instruments

With temperature-controlled cooling oil circulating through its integral 45,000 rpm, HSK-E40 spindle, the Ultimate Die and Mold 400/5X Vertical Machining Center from Mazak is powered by an 18.5 hp motor that ensures stability over long periods of high-speed operation.

How to Aggressively Tackle Full Five-Side Machining of Increasingly Complex Medical and Dental Parts

The DA300 5-axis vertical machining center from Makino is ideal for single setup, multi-side accessibility or quick and efficient full-contouring of a wide variety of complex medical and dental products.

Automated Precision Milling of Surgical Instruments and Medical Components

Featuring a 320 mm diameter NC swiveling rotary table with a multi-clamp system, the working area of a high performance Hermle C 22 U 5-axis machining center is used by Fetzer Medical to machine surgical instruments and complex medical components to customer specifications.

High Speed, Ultra-Compact, Dual-Axis Rotary Table for Machining Small Complex Medical Parts

The TRT70 dual-axis rotary table from Haas easily fits the smallest machining center or mounts on one end of a larger machine’s table, freeing up the remainder for additional fixtures or vises.

Smart Machining of Medical Implants, Medical Components and More

The Mikron MILL S 400 U from GF Machining Solutions provides levels of reliability, traceability and accuracy that are ideal for mold and die machining, as well as post-processing parts and molds produced with additive manufacturing systems.