Maintenance

Filter by Process Zone:

Plug-and-Play Cobot Programs Like a Smartphone

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

ALL-IN-ONE SPINDLE-BEARING LUBRICANT

Metworx Spindle Oil 2 is designed to meet the demanding service requirements of bearings in extremely high-precision, tight-clearance applications.

A FORMULA FOR VIRTUALLY EVERY APPLICATION

DiaGrind 535 is recommended by machine manufacturers for gear grinding, hobbing, honing, and cutting.

LITERATURE DETAILS ABRASIVE LAPPING SOLUTIONS

Products developed by metalworking specialists and chemists for manufacturers of all sizes and volumes.

MANUAL AND POWER CHUCK BOUNDARY LUBRICANT

Environmentally friendly grease provides exceptional mechanical stability, very high load carrying capacity, and excellent water- and moisture-resistance.

REMOVES ULTRAFINE MISTS & FUMES

Modular filtration solution can be easily expanded and comes with no-leak guarantee.

VAC-U-MAX Achieves Milestones

Doan Pendleton is appointed president as the company celebrates 65 years in business.

Beckwood to Retrofit Draw Forming Press

Branch Manufacturing selected them to retrofit a 750 ton straight-side draw press originally built in 1979.

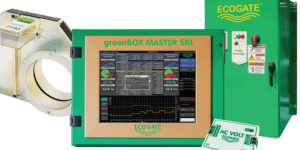

Industrial Ventilation Control System Cuts Electricity Costs

This system from Ecogate saves users 68 percent on fume/dust/mist collection system electricity costs by monitoring what their machines are doing at all times and adjusting their ventilation so they only receive suction where needed, when needed, in real-time.

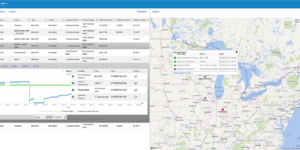

IoT-Based Remote Sensing Service to Monitor Industrial Dust Collectors

Subscribers to this service from Donaldson Torit receive real-time issue detection and alerts to help reduce unscheduled maintenance.

Quaker Houghton Acquires Norman Hay

This deal expands their global footprint in specialty chemicals, operating equipment, and services to industrial end markets.

How to Get Smart with Fluid Application for Metal Forming

The SmartFlow controller from Unist provides advanced press control integration, fluid usage tracking, process monitoring, and enhanced diagnostic and maintenance tools to keep the press line running productively with the right amount of lubrication.