Material Handling

Filter by Process Zone:

Orbital Wrapper Now Has Touch-Screen Controls, Built-In Training Guides

TAB Industries’ clear, colorful, visual menu structure enables intuitively easy setup, operation and preventative maintenance –– at no extra charge.

MOBILE ROBOT FOR SEMICONDUCTOR PRODUCTION

KUKA’s wafer-handling solution from a single source is comprised of four components: a standardized automated guided vehicle (AGV); an LBR iiwa lightweight robot; sophisticated wafer handling application including gripper; and software.

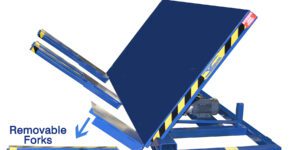

REMOVABLE FORKS ENHANCE VERSATILITY

Tilt table facilitates manufacturing and assembly operations that require working in horizontal and vertical positions.

Dual-Purpose Automatic Tool Changer

Programmable press attachment does everything by itself, freeing employees to work on more complex tasks.

FULLY INTEGRATED LASER AUTOMATION

Multifunctional system controls production from loading, cutting, sorting, and unloading to finished-parts storage.

THREE SMART TOOLS FOR SMART FACTORIES

Festo is distributing a new line of magnetic grippers and giving you the ability to design your own 2- or 3-axis industrial robot.

ONE CRANE, TWO AUTOMATION OPTIONS

Overhead crane combines lightweight aluminum rail systems with semi- or fully automated “smart” material-handling solutions.

TWO NEW PRODUCTS FROM BILSING

Ultrahigh-modulus carbon fiber composite tooling and double-blank detection for hot or cold stamping.

INVERTERS AUTOMATE STACK-FLIPPING

Machine minimizes damage to blanks and enables same die to be used for stamping left-hand and right-hand mirror-image components.

Custom Forklift Attachment Enhances Stamping Plant Productivity

Caldwell Group tool facilitates delivery of 11-to-12-ton steel coils at MiTek USA.

OnRobot Grippers Receive UR + Certification for Seamless Operation

The certified URCap software provides a unified interface for OnRobot’s new versions of RG2, RG6, and VG10 grippers with Universal Robots (UR).

Dynamic Scrap Handling Increases Coil-Fed Laser Blanking Speed

Coil-fed laser blanking systems from LaserCoil rely on a series of dynamic profile conveyor lanes that independently adjust, reposition and automatically shed scrap to maintain a clear path for the cutting process.