Metal Forming & Fabricating

Filter by Process Zone:

Flexible 3D Printing of Components with Finished Part Quality

Using selective laser melting driven by self-adjusting and learning algorithms to create very small, highly complex parts from different materials, the Lasertec 30 SLM five-axis powder bed fusion machine from DMG MORI has an intelligent powder module that can change materials in under two hours.

Printing Parts for Extreme Temperature, Highly Corrosive, Marine-Grade Environments

Printing 316L stainless steel with the Studio System from Desktop Metal is another step to fundamentally changing the way metal parts are designed and manufactured for the most demanding applications.

Shaping the Future of Manufacturing

3D printing capabilities in various additive systems from Cincinnati Incorporated range from quickly creating prototypes to unattended production of complex parts, with part simulation in all stages of fabrication that dramatically reduces waste in part design and accelerates advancement to production.

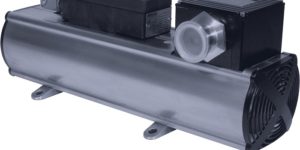

Blowers for Precise Gas Control in Additive Manufacturing

Side channel blowers from Becker permit precise control of gas flow and removal of contamination within the build chamber of the machine used in selective laser melting operations.

3D Printing Improves Aircraft Component Design

Betatype pushed laser powder bed fusion beyond its standard processes to create a more complex, higher density electrical generator housing for Safran Electrical & Power that performs better and has fewer parts, shorter delivery times and lower operating costs.

How to Use Multi-Jet Fusion for Economical Small Batch Production

Partfinder software from Additive Innovation makes the economical production of small batches and spare parts possible with the multi-jet fusion process by automatically searching large volumes of data for components that are suitable for 3D printing.

Using Robots to Print the Future

Robotics-based additive processes from ABB offer inherent flexibility of motion and processing power to produce a component as close to near net shape as possible in a much-compressed time period.

Scalable 3D Printing Systems Meet Evolving Business Demands

Modular production platforms from 3D Systems help shops evolve and grow by accelerating their time-to-market with ultra-fast production of highly accurate and repeatable parts, without regard to a minimum order quantity.

3D Printing Beyond Big on a Smaller Budget

Starting at under $200K, the WorkCenter 500 large format 3D printer from 3DP provides users with an extra-large format and affordability without sacrificing build volume quality or throughput.

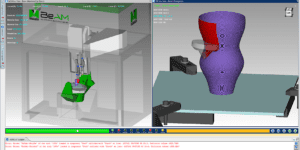

Using Toolpath Simulation for Faster Build Rates of Extreme Complexity

BeAM uses software from CGTech to verify millions of lines of code used to drive their high-speed, five-axis powder-based directed energy deposition additive systems, creating a layer of machine protection and simulation accuracy otherwise impossible to achieve.

Stay Sharp for Maximum Tool Life

To prevent lower quality parts and frequent tool replacement, keep your punch press tooling sharp and well maintained to achieve the greatest number of hits possible for the best possible return on your investment.

Finding Balance: Robotic Machine Tending Tips

Robotic automation of machine tending can add value to operations in more ways than one. By considering these concepts and combining best practices with high performance robots and peripherals, operational inefficiencies will diminish, paving the way for a more productive future.