Metal Forming & Fabricating

Filter by Process Zone:

The Day the Robots Take Control: Part Two

Is the robot revolution really such a bad thing? As automation and robotics sweep through manufacturing, Smart Factories driven by digital information are slowly emerging as an ultra-lean answer to the skilled labor shortage and other competitive issues.

Technical Service in the Era of Industry 4.0

As machine tool manufacturers work on enabling technology to make the Smart Factory possible, the field of machine service and support has started to drastically minimize the window of lost productive time that shops must deal with.

Yes, You CAN Automate Without a Robot

The average shop taking their first steps into automation doesn’t need to break the bank by investing in lights-out production with advanced robotics. There is a simpler, less expensive way to impact your bottom line.

Beckhoff Automation Appoints New President

Kevin Barker now manages their business operations across the U.S.

Absolute Machine Tools is Sold to ESOP

This allows employees to gain a beneficial ownership interest in the company without any personal monetary investment.

Motion Industries Acquires Axis New England

This deal expands their presence in advanced machine automation, motion control, robotics, and machine vision.

Increase Tool Life with Preventive Maintenance

Deliberately pull a die out of the stamping press for tool maintenance even though it is still producing perfect parts? That’s right. Don’t wait for that next emergency to shut everything down to put out fires. You can actually reduce downtime by regularly scheduling preventive tool maintenance that provides longer tool life, fewer scrapped parts and improved productivity.

TTG Hires Corporate Sales Executive

Kelly Connors will help solve customer tooling problems and foster long-term relationships.

KMC Controls Division Expands

Their Controls & Automation division now provides industrial control panels, systems automation and integration for outside markets.

Easy Robotic Automation for a Stronger Workforce and Better ROI

Smart manufacturing tools are helping shops of all sizes deal with labor shortages and production inefficiencies. When implemented and managed correctly, these tools can aid human workers, create a more productive workforce and increase overall competitiveness.

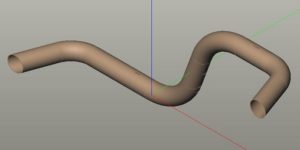

Consider the Big Picture When Manufacturing Complex Tube Assemblies

Fit-up, fixturing and assembly of multiple tubes can be difficult when coping, mitering and other secondary operations are required after bending. This is where new tube fabrication technology shines. Though it may bill out at a higher machine rate/hour, the time, material, tooling and labor it saves delivers a lower cost per assembly – and higher profitability.