Metal Forming & Fabricating

Filter by Process Zone:

Automated Processing of Angle and Flat Bar Reduces Labor Costs

The Anglemaster-663 from Peddinghaus uses three punch stations per hydraulic press to automate punching, nibbling, shearing and marking of angle and flat bar.

Larger Pump for Economical Abrasive Waterjet Operations

For educators, job shops, fabricators, and manufacturers who need an economical abrasive waterjet, the GlobalMAX 10 hp pump from OMAX delivers 30,000 psi pressure to the cutting nozzle of a GlobalMAX JetMachining Center.

Ultra-High Purity Nitrogen Gas Generators for Laser Cutting Applications

Nano GEN2 nitrogen gas generators from Nano-Purification Solutions provide operating pressures of 145 psig and 232 psig and boost pressures to 5,000 psig for flow rates with purities from 95 percent to 99.999 percent.

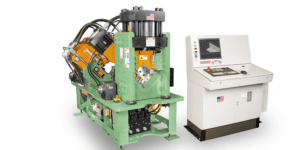

Efficiency-Driven Fiber Laser Cutting, Turret Punch Press Operations

The Muratec LS3015GC fiber laser from Murata Machinery cuts through steel, stainless steel, aluminum, brass, bronze and other ferrous and nonferrous metals, while their Motorum M2044TS turret punch press uses a servo-electric punch drive system that incorporates the latest ram drive design.

Advanced Plasma Cutting Systems that Meet Modern Fabrication Demands

Messer Cutting Systems offers the MetalMaster Xcel plasma cutting machine with traverse speeds of 3,000 ipm and high acceleration drives, the MetalMaster 2.0 unitized cutting machine and the MetalMaster Evolution unitized cutting machine.

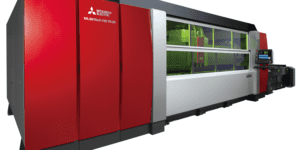

Industry 4.0 Fiber Laser Cutting System

In line with Industry 4.0 real-time process, consumption and service monitoring, the Advanced 800 eX-F fiber laser cutting system from MC Machinery incorporates an all-new M800 control with enhanced industry-leading functionality.

Game-Changing Direct Diode Laser Cutting Technology

The Optiplex 3015 DDL 6 kW direct diode laser cutting system from Mazak Optonics utilizes flying optics, a two-pallet changer and a high performance digital drive package.

Faster Turret Press and Press Brake Setups, Improved Slitting of Thick Materials, and Fiber and CO2 Laser Cutting

Mate Precision offers QCT Metric quick change tool-less tooling, the Versadie HD clamp clearing system that uses unique design features to improve slitting thick materials, and Laser Accessories to help shops improve their fabricating efficiency.

An Alternative Deslagging System for Small Steel Service Centers

With a 37 in working width and minimum part size of 11 in x 2 in that is suited for small steel service centers in particular, the SMD 133 DRS machine from LISSMAC handles slag removal, deburring, and edge rounding of plasma and oxyfuel cut parts.

Faster Processing of Aluminum, High Strength Steel and Brass Parts

The TLH 5-axis fiber laser system from Komatsu provides faster processing of aluminum, high strength steel or brass parts, and excellent cut quality on hot stamped parts.

New Waterjet Pump Technology Reduces Cutting Times by Up to Half

PRO-III 125 hp and 60 hp pumps from KMT Waterjet can cut metal, aluminum, steel, stainless steel, titanium, rubber, plastic, glass and other materials in up to half the time, including 5-axis three-dimensional cutting operations, with significant savings in abrasive consumption usage.