Metal Forming & Fabricating

Filter by Process Zone:

Press System with In-Die Laser Welding Eliminates Time-Intensive Labor

The laser welding, parts assembly and cut-off operations inside the pneumatic stamping press system with in-die laser welding capability from Airam eliminate time-intensive labor, improve repeatability and reduce material handling without sacrificing production speed.

U.S. Machine Tool Orders Stay Strong

Orders totaled $447 million in December as the market picks up speed during the first quarter of 2018.

Cincinnati Incorporated Names ProNEST as Preferred Partner

The software from Hypertherm provides seamless communication and optimization for their CO2 and fiber laser cutting systems.

Fiber Laser System Machines 3D Parts

The five-axis LT-FREE fiber laser machine from BLM performs traditional cutting, drilling, punching and milling operations that are normally carried out in sequence on separate machine tools.

Superior Bending with Unparalleled Productivity

The TruBend Series 5000 press brake from TRUMPF is equipped with a ToolMaster for automatic tool changes in seconds and achieves unparalleled productivity by combining high axis speeds and acceleration rates with innovative operating aids.

Cost Effective Brazing of Light, Thin Section Parts Used in Power Generation

The horizontal-loading MetalMaster vacuum furnace with 2-bar gas quenching from Ipsen features a 36 in x 36 in x 72 in graphite work zone with a carbon steel gas distribution plenum and graphite heating elements, as well as a 3,000 lb load capacity.

The ROI Threshold

What happens when demand for parts from a supplier increases so that an OEM can scale up production? Determining the ideal time to transition to a more economical alternative can be challenging, but a “one-stop” parts supplier can scale with demand, facilitating the transition to hard tooling, mixing and matching metalworking techniques for multi-component assemblies, and incorporating hybrid and secondary tooling approaches to further reduce costs.

Making Fabrication More Efficient in Power Plant Construction

During construction, miles of pipelines are fabricated from a variety of materials with variable diameters and nominal widths. To save time and reduce costs, automated CNC tube bending machines can bend, measure and adjust 3D pipe systems in a single operation – without welding – with a measuring system integrated into the bending tool.

Robot-Assisted Sawing for Greater Productivity

Robot-assisted systems are taking over more and more tasks that follow the sawing process, starting with removal of the cut parts and continuing on through deburring, weighing, centring and marking, all the way into sorting and stacking on pallets or in containers.

Heavy Duty Inert Atmosphere Furnace for Heat Treating Turbine Components

The heavy duty No. 1039 inert atmosphere furnace from Grieve reaches 2,000 deg F by using ICA wire coils supported by vacuum-formed ceramic fiber installed on all interior surfaces, including the door and beneath the hearth.

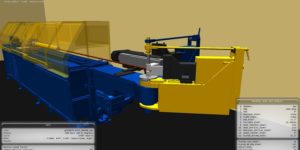

The Next Step in Precision Tube Bending

The Opt2Sim tube bending machine simulator from Unison accelerates the generation of error-free programs for bending tubular parts and includes powerful collision detection capabilities that can be used to avoid and verify a wider range of problem scenarios.

Bending Complex Geometries for Power Plants

The transfluid t bend DB 622 CNC R/L mandrel bending machine, the fully automatic t bend DB 2090 CNC VE machine, the t cut RTO 628 chipless orbital cutting system, and the REB 632/SRM 622 CNC combination machine from Advanced Fabricating Machinery fabricate pipe for meeting the highest loading requirements, including tight bending radii to ensure optimum surface area for thermal transfer.