Metal Forming & Fabricating

Filter by Process Zone:

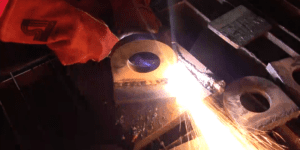

High Speed Plasma Cutting System Slashes Operating Costs

The Hypertherm XPR300 plasma cutting system on the PlasMAX high speed cutting machine from Controlled Automation increases cut speed, dramatically improves productivity, triples realized consumable life in many applications, and slashes operating costs by over 50 percent.

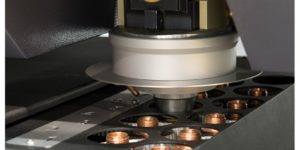

Automatic Nozzle Changer Reduces Downtime on High Speed Fiber Laser

The Electra FL high speed fiber laser cutting machine from LVD Strippit includes an integrated nozzle changer option that features storage for ten nozzles for greater autonomy, reduced piercing times and increased overall throughput on the machine.

Cold Machining with Ultrafast Lasers

Femtosecond and picosecond laser systems produce high quality small features with high dimensional accuracy, with minimal burring and debris that reduces or eliminates post processing. However, these systems are expensive, so choose the laser and system wisely. Here are some things to consider.

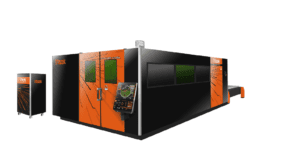

High Speed Cutting

Here are some of the newest advances in high speed laser and plasma cutting systems that can help shops increase their productivity, add more capacity, and lower their operating costs.

Faster Than Ever: Revolutionary Laser Technology Changes the Game

The OPTIPLEX 3015 DDL laser cutting machine from Mazak Optonics uses direct diode laser technology for faster cutting speeds than fiber lasers of like power and wall-plug efficiencies of 45 percent as compared to 35 percent for fiber.

Air Assist Cutting Increases Cutting Speed, Lowers Production Costs

With its human-machine interface and user-friendly touchscreen controls, the CL-960 6 kW Fiber Laser from Cincinnati Incorporated uses advanced laser cutting capabilities to process thin material faster while cutting up to 3/4 in thick steel.

Rebuilding American Manufacturing, One Veteran at a Time

A perfect storm: One million veterans leave the service every five years as a projected two million manufacturing jobs go unfilled in the U.S. over the next decade due to lack of skilled labor. Take a closer look at how veterans are forging new careers in metalworking through Workshops for Warriors – and how manufacturers can put skin in the game with support.

Deep Etching with a 2D Fiber Laser

Laser etching is a useful tool, but its limits as a light surface effect are apparent when a part number needs to be visible through paint or a powder coat. In these cases, deep etching can provide a simple solution – the trick is finding the right combination of hertz, laser wattage, focal diameter, and gas for your specific material.

Metal 3D Printing for Land, Sea, Air and Space

When a submarine manufacturer saved significant time and cost by using Electron Beam Additive Manufacturing to 3D print a titanium Variable Ballast tank, the technology became the only industrial-scale metal 3D printing process with approved parts for land, sea, air, and space applications.

Approaching Removal Jobs from a New Angle

Efficient attachment removal has always been tricky. Without the ability to mechanically position the tool so that a closer cut can be achieved with less residual metal, workers were forced to deal with the drawbacks of traditional removal processes. But not anymore: A small alteration has made a huge impact on the attachment removal process.