Metal Forming & Fabricating

Filter by Process Zone:

Custom Hydraulic Press Solutions

Greenerd Press showcases their extensive hydraulic press capabilities to 40,000 tons and bed sizes exceeding 240 in with a variety of styles ranging from gap frame and straight-side to die-spotting and forging presses.

Coil Handling Lines for Metal Stampers

CHS Automation/Pneumatic Feed Service displays an assortment of coil handling lines for metal stampers, including advanced servo feed rolls, straighteners, coil reels, cradles, air feeds and other equipment.

Laser Blanking Line

The new laser blanking line from Schuler Incorporated combines cutting-edge laser methods with continuous coil feeding for maximum performance and flexibility, utilizing DynamicFlow Technology that is energy efficient and can process a variety of materials such as high-strength steels, with repeat accuracy and edge quality. The new line cuts blanks from a continuously fed aluminum coil. Using three laser heads in parallel, this blanking line can cut blanks with a thickness of 0.8 mm to 3 mm and a width of up to 2,150 mm.

Advanced Slitting System for Multi-Blanking and Slitting Lines

The new Fully Automated CNC Programmable Slitting Head from Red Bud Industries is a highly advanced Slitting System for both Multi-Blanking and Slitting Lines with a Head that is fully automated to completely set itself up without any operator intervention in less than two minutes.

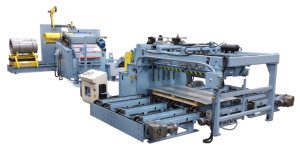

Advanced Roll Feeding, Cut-To-Length Systems

COE Press Equipment highlights their Cut-to-Length Line (CTL) that provides fabricators and metal stampers with cost savings associated with producing blanks in-house, along with a conventional coil line featuring its ServoMaster SM2-18 Zig-Zag Roll Feed.

Robot Loads Deep Drawn Parts Into Press

Triform Sheet Hydroforming and Beckwood Press demonstrate sheet hydroforming with 3D tools and simulation software in action, along with robotic automation to tend the machine tools.

Straight Side and C-Frame Stamping Presses

Maxi Stamper eccentric-geared tie rod straight side presses from HEIM are available in the 300 ton to 1000 ton range. Users select the stroke, speed, shut height and bed area.

Direct Drive Servo Former Presses

AIDA-America offers DSF presses for producing pipe flange parts, difficult drawing applications, blanking and other stamping operations.

3D Printing Combines with Medical Implant Design Software

Targeting medical, surgical, and orthopedic designers and manufacturers, C&A Tool and WITHIN have launched a patient-specific, metal-implant design and manufacturing program using EOS Direct Metal Laser-Sintering software to facilitate the creation of highly customized products that improve osseointegration or bone growth.

Laser Melting: Strike While the Iron is Hot

As a market leader in manufacturing irons for the home, Rowenta uses tooling from Hofmann Innovation that was built by combining conformal cooling with inserts that are produced generatively using the LaserCUSING laser metal melting method and conventionally tempered surfaces at critical points in the webs, difficult core zones, or atypical material areas.

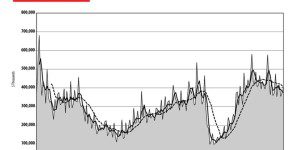

September Manufacturing Orders Increase 5.8 Percent from August

USMTO announces September U.S. manufacturing technology orders totaled $397.57 million, up 5.8 percent from August but down 31.1 percent from September 2012.

The Internet of Things

Want to know what lies ahead in manufacturing? Markus Löffler and Andreas Tschiesner of consulting

firm McKinsey & Company share some valuable insights from executives at Robert Bosch who discuss the technology-driven changes that promise to trigger a new industrial revolution that will affect how your shop operates — and competes.