Metal Forming & Fabricating

Filter by Process Zone:

Selective Laser Melting Systems for Any Size Shop

With a build envelope of 11 by 11 by 14 inches, SLM Solutions’ SLM 280 2.0 is ideal for medium-to-high-volume additive manufacturing. With its build envelope of almost 2 square feet, the 12-laser NXG XII is designed for peak production.

Quality Mass Production with Metal Binder Jetting IS Possible

Hexagon’s Simufact Additive powerful and scalable process simulation environment for first-time-right optimization of metal binder jetting (MBJ) predicts and automatically corrects for final distortion and residual stresses of 3D-printed parts.

Software Add-On Saves Time and Improves Consistency

DP Technology’s Esprit Additive for Powder Bed is compatible with any file supported by SolidWorks. The add-on application streamlines production by eliminating the need to repeatedly define manufacturing information.

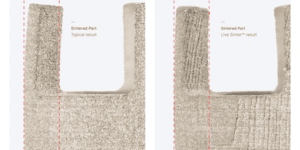

Simulation Software Takes Guesswork Out of 3D Metal Printing

Live Sinter enables inexperienced 3D-printer operators to consistently produce accurate parts using Desktop Metal’s Shop System and Production System machines. The software automatically overcorrects for the shrinkage and distortion inherent in sintering.

Sigma Labs Creates New Directed Energy Deposition Application

A partnership with Northwestern University expands in-process quality assurance technology across a broad array of 3d printing processes.

How to Minimize Post-Processing Headaches for 3D-Printed Parts

Although 3D metal printing is becoming more popular, finishing remains a challenging and arduous task. Understanding how post-processing works and how to measure results will help you optimize this crucial step.

Eight Tips for Getting ERP Right the First Time

Done right, enterprise resource planning (ERP) identifies and systematically eliminates activities that eat into profits. Here’s how to select a program and partner that will facilitate rather than frustrate the process.

Electric Rolling Device on Tube End Forming Machine

The addition of a CNC electric rolling device on BLM Group’s E-Form machine offers repeatability in part production. With punches reaching up to 10 tons of force, E-FORM molds tubes of various materials up to 30 mm in diameter.

Three Manufacturing Trends the Pandemic Fast-Tracked

National Association of Manufacturers Chief Economist Chad Moutray explains how pandemic-driven disruption is influencing digitization and data sharing, re- and near-shoring, and hiring.

The Six Things COVID-19’s Manufacturing Winners Have in Common

AMT – The Association For Manufacturing Technology President Doug Woods outlines the six transformative technologies that are helping companies meet swiftly changing market demand without sacrificing quality or employee safety.