Metal Forming & Fabricating

Filter by Process Zone:

Deburr, Polish, Clean, and Dry Parts in 5 Seconds

By rotating media instead of parts, Bel Air Finishing’s AutoHone robotic deburring machine eliminates scrapes and chips that occur when parts collide with each other in tumblers and centrifugal disk finishers. Parts are secured for deburring and polishing in an automated process.

Totally Tubular: Take Profile Design to the Next Level

One of the fastest-growing sectors of North American metal manufacturing is laser processing of tubes and profiles. Design software and machines that automatically perform multiple manufacturing steps are making this complicated fabrication process cost-effective for smaller companies.

Think of Weld Traceability As Your Company’s Unofficial Insurance Policy

Robotic welding cells with arc-monitoring and -reporting capability provide peace of mind in two ways. They ensure consistent production and automatically collect and store data a fabrication company can easily share with customers that impose traceability requirements.

Best Practices For Avoiding a Burr in the Saddle

Deburring ensures parts fit perfectly during welding or final assembly. This leads to higher-quality products and more efficient workflows that will save your shop time and money – and improve its bottom line.

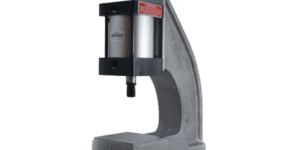

Don’t Get Depressed: There Is A Solution For Your Application

Pneumatic, hydraulic, and electric presses are available in a wide range of models that offer an ever wider range of force, position accuracy, and speed capabilities. Bimba technical experts outline the pros and cons of each press type to make your decision easier.

Ready for the Rebound? This Manufacturer Is

Nuts, screws, and bolts comprise one of metal manufacturing’s most competitive product niches. As it works to gain market share by capitalizing on pandemic-driven supply chain disruptions, this Illinois fastener manufacturer and distributor illustrates the art of decision-making in uncertain times.

Cut Overall Cycle Time With On-The-Fly Laser Marking Machines

Shaving every second possible from each process is a key objective for high-speed, high-volume manufacturers. Laser marking on the fly helps by recording data on a moving target in milliseconds. Pryor Marking Technology’s Alastair Morris explains.

New Line Of Dot Peen And Fiber Laser Markers

Dapra Marking Systems introduces the part-marking technology of Spanish manufacturer Datamark Systems to North America. Headlining the new offerings is a series of truly portable dot peen markers.

Time-Saving Tool Cleaning and Laser Marking Join with Robot Loader

Walter Helicheck Plus and Helicheck Pro machines from United Grinding North America use robotics to increase the speed and efficiency of cutting tool production and inspection.

Dot Peen Marking Machine Keeps Up With The Flow

SIC Marking’s extremely compact i-speed with pneumatically integrable system uses continuous vibrating dot peen technology to mark up to 10 characters per second in extremely high-speed production environments.

All-in-One Benchtop Marker With Integrated Control Unit

The control unit for the all-in-one Markator FlyMarker mini-Station dot peen marking system from Rocklin Manufacturing is integrated in the housing. Electromagnetic-driven marking pin eliminates need for compressed air supply.