Metal Forming & Fabricating

Filter by Process Zone:

Cutting Software’s Collision Prevention Can Shave Downtime 80%

Lantek’s 2020 version contains more than 100 improvements that emphasize process efficiency as well as remote working for users. Lantek Expert, Lantek Flex3d, Lantek Integra, and Lantek MES Manager have evolved with algorithms to meet market needs.

Whatever the Surface, Find Your Finish Here

Weldcote offers a full line of surface conditioning products for all kinds of metal materials. From ultra-fine finishing to removing rust and paint, the wheels and pads for even hard-to-reach areas are covered in this lineup.

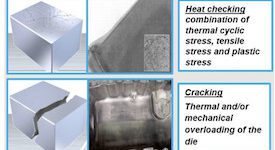

Choose the Right Die Material for High-Pressure Die Casting

In the HPDC industry, steel selection can be the most costly problem in the supply chain. An Uddeholm expert discusses how to solve the major causes of die failure: heat checking, soldering, erosion and cracking.

Automated Laser Cladding for 3D Metal Additive Repair

Optomec integrates Fanuc LRMate 200 robotic loading with its Huffman line of production 3D metal additive repair machines for high-volume turbine work and myriad industrial applications. Autonomous batch processing expedites cycle times and frees the operator to add value elsewhere.

Accelerate New Product Intros with Machine-Agnostic Data Exchange Format

Siemens has extended its ODB++ data exchange format for a complete end-to-end digital solution covering design, process, and manufacturing information flows. A complete digital twin of the electronics manufacturing flow helps users realize their Smart Factory or Industry 4.0 initiatives.

Consider Retrofitting Obsolete CNC Functions

Servo Products’ Orion CNC retrofit package helps gives job shops an affordable alternative to replacing a whole milling machine. By replacing or adding controls, low- to mid-volume operations can reduce downtime and jack up profit margins.

Pandemic Underscores Need for Supply Chain Agility

For almost a decade, machine tool consumption in the U.S. has increased and China’s has decreased. As global supply chain emergencies accelerate a manufacturing migration to the U.S., metal fabrication and machining companies that use manufacturing as a service (MaaS) platforms stand to benefit.

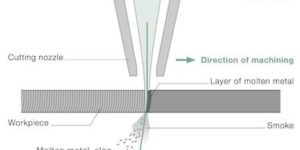

Laser Cutter That Thinks for Itself Opens the Door to a Fully Automated Process

Trumpf’s Active Speed Control uses artificial intelligence to completely eliminate the need for an operator to monitor cutting and, if necessary, tweak parameters. The technology automatically adjusts feed rate to ensure part quality when cutting plate with chemistry, thickness, or surface condition variations.

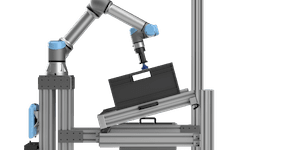

Autonomous Bin Picking Kit Provides the Vision Minus the Collision

Machine tending steps into a new playing field with Universal Robot’s ActiNav, where pick and place accuracy exceeds dropping into a box. With minimal operator intervention, parts are inserted into a fixture for their next step in the processing journey.

Easy Wins: Adapting to a New Manufacturing Reality

As many fabricating and metalworking companies seek to revitalize production in these trying times, a new sense of urgency is prompting creative approaches to automation. While each shop will forge a unique path to its own new reality, they’ll share common challenges and solutions.

Auto Racing-World Manufacturer Cuts New Path to Profitability with Automated Metal Cutting

The world’s top engine builders and auto enthusiasts rely on Borla Performance Industries exhaust systems, but parts were taking too long to program and produce. Switching from CNC machining to automated plasma cutting is drastically reducing cycle times.