Metal Forming & Fabricating

Filter by Process Zone:

How to Optimize Sawing Operations

A sawing specialist asks and answers four basic questions about feed rate and feed pressure, blade life, determining cutting feed and cutting speed, and optimizing tooth selection.

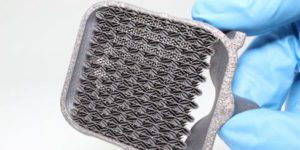

The Problem With Particle Porosity and How to Fix It

3D printing powders maximize part quality, but many are the suppliers from which to choose. In this Q&A, the president of GEMCO notes the industry is turning to contract powder processors for sophisticated heat treatments that improve quality.

Manufacturer of the Year Outlines Company’s COVID-19 Response

At least one of this Georgia sheet metal fabricator’s 130 employees has tested positive for the coronavirus. President Bruce Hagenau shares how METCAM is keeping the rest of the team – and their families – safe.

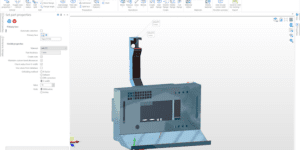

Ultimate Nesting for Punching Machines

The latest RADAN software for sheet metal fabrication provides savings on raw materials and quicker nesting production. Users can produce more parts per sheet, so it takes less time to produce a batch – saving about 50 minutes per day for 80 nests.

New Hires at Behringer Saws Expand Sales and Service

Together, the company’s new insides sales engineer and field service manager bring more than 10 years’ experience to Behringer.

Morphing into Medical, Components Maker Heals Itself

Now cranking out 500,000 face shields per week, Mursix used its MC Machinery CO2 laser and wire EDM to switch gears from sinking auto parts and turned itself into a major PPE manufacturer. The company’s co-owner, a former ER nurse, hustled with her engineers to develop a medically compliant prototype that went into production within just a few days.

3D Printing in Aluminum F357 for Thin-Walled Heat Transfer Applications

Aircraft-grade alloy is ideal for additive manufacturing of aerospace, military, and defense components, making it a logical addition to VELO3D’s portfolio. The 3D printing of parts can actually replace applications where casting is used.

Algorithm Ends Collisions, Damaged Cutting Heads, and Shutdowns

Lantek’s Intelligent Collision Avoidance (ICA) detects when sheet metal contours or scrap pieces pose a risk of interfering with the cutting head. And when collisions are averted, fiber laser cutting productivity soars.

Good News for Transportation, Aerospace: DED Developed for Aluminum 3D Printing

Optomec’s LENS Directed Energy Deposition systems feature advanced capabilities for use in additive manufacturing and repairing aluminum alloys. Its process parameters for aluminum alloys now provide excellent surface finish, high deposition rates and a density of ~99.9%, says applications engineer.

Compact Tube Configurations Made Simple

tranfluid’s MB 642 mobile bending machine will fabricate all kinds of tubes used in hydraulics, including those with thin tube walls. But this bending system is so compact, all you need is one square meter of production area in which to operate.

VELO3D’s First Meter-Tall 3D Metal Printer Sold to Knust-Godwin

The next-generation Sapphire machine will print up to 1 meter in height, making it the tallest laser-powder additive manufacturing system. It’ll debut its patented SupportFree process in the creation of industrial parts in the oil and gas industry.

Staying Healthy for the Healthcare Workers They Serve

Dewalt is serious about staying the course so their people can serve myriad frontline folks during the pandemic. A lengthy list of protective protocols has kept their operations going to meet the daily demands of their business partners.