Metal Forming & Fabricating

Filter by Process Zone:

FABTECH 2019: Metalform (Part One)

Here are some of the metalforming tools, machinery and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

FABTECH 2019: Metalform (Part Two)

Here are some more of the metalforming tools, machinery and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Cutting-Edge Forming Technologies

TwinServo press technology and the economic production of composite parts from Schuler enable press rooms to produce resources more efficiently so they can remain marketable and competitive.

Precision Mechanical and Hydraulic Presses

Hammer Presses by EDPS builds and installs mechanical and hydraulic power presses for all types of metal forming applications, along with a full line of press room accessories, preventative maintenance programs and 24/7 support.

Removing Barriers in High Pressure Fabrication

High Pressure Warm Forming technology and Hot Isostatic Press systems from Quintus emerge as cost effective approaches to forming Ti-6Al-4V titanium and streamlined post processing for leaner AM operations.

Corrosion Inhibitor Packaging Protects Metal Parts

VCI films and bubble bags from Daubert Cromwell protect steel, aluminum, copper and other metal parts from rust and shipping damage.

How to Get Smart with Fluid Application for Metal Forming

The SmartFlow controller from Unist provides advanced press control integration, fluid usage tracking, process monitoring, and enhanced diagnostic and maintenance tools to keep the press line running productively with the right amount of lubrication.

New Advances in Servo Press Stamping Operations

Exclusive Allen-Bradley-based servo press controls combine with the new DSF-C1(A) series direct-drive gap frame servo press from AIDA-America to maximize stamping productivity and profit in the press room.

Press Automation and Data Collection

ShopFloorConnect V6 software and the SmartPAC PRO press automation controller from Wintriss Controls enables networked users to share the entire contents of each programmed setup on a single screen in an Industry 4.0 environment.

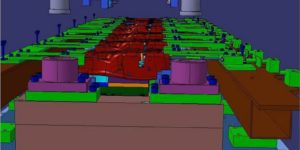

Single Source Capabilities for Die Design Through Manufacturing

Tooling Tech Group is a single source supplier of everything from die design, simulation and engineering through to die build, repair, try-out and production stampings.

Economical Process Monitoring of Metal Forming and Stamping Operations

The intelligent Brankamp X3S real-time process monitoring system from Marposs immediately identifies manufacturing faults and part or tool variations to optimize machine efficiency, improve part quality, and limit unplanned downtime and tooling costs.

Roll Coater Lubrication for Tough Stamping Environments

The extremely rugged Minicoater roll coater lubrication system from LSP Industries dispenses precise amounts of fluids through a unique built-in manifold system when the press cycles for partial strip lubrication and top and/or bottom-only lubrication.