Metal Forming & Fabricating

Filter by Process Zone:

Next Steps in Servo-Hydraulic Press Design

A new servo-hydraulic press from Greenerd Press automatically sets itself up after the operator selects the press operation with simple, icon-based cycle profiles. Custom press cycles are stored in over 1,000 different recipes and recalled instantly with a bar code reader.

When Your Equipment Absolutely, Positively Has to Be There Now

The Express Delivery Equipment from COE Press Equipment includes machinery in varying sizes for customers who need equipment immediately to keep their operations running smoothly.

Smart Servo-Electric and Sheet Hydroforming Press Technologies

The EVOx servo-electric press and Triform deep draw sheet hydroforming press from Beckwood Press feature intuitive controls, recipe handling, data acquisition for part traceability, remote field support and IoT connectivity for maximum uptime and predictability.

How to Configure Network Cameras from a Web Browser

With reliability and speed needed for traceability, error-proofing, vision-guided robotics and other applications, BVS Cockpit software from Balluff does what sensors can’t do, with all of the functions needed to operate SmartCameras.

Die Design Software Includes Die Try-Out on Screen

Even before material is ordered to build a die, the Die Debugger tool from Accurate Die Design Software detects mechanical mistakes on the computer screen during die design that are usually found during die assembly or in the tryout press.

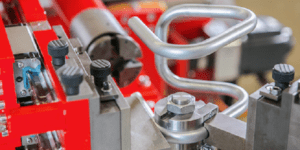

FABTECH 2019: Tube & Pipe

Here is some of the tube and pipe fabrication equipment that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Tube Processing for High-Tech Medical Applications

Advanced forming and bending machines from transfluid deliver accurate tube processing of high and ultra-high strength materials.

Laser-Induced Breakdown Spectroscopy for Fast, Accurate Carbon Measurement

The Niton Apollo handheld LIBS analyzer from Thermo Fisher Scientific provides true field mobility and enhances productivity for material verification by fabricators and scrap recyclers.

Fabrication Bending Made Easy

For manufacturers who bend tube and pipe for their finished products, Fabrication Benders from Huth-Ben Pearson easily bend square, round and rectangular pipe and tubing, solid bar and schedule/thick wall pipe.

Advanced Tube and Sheet Metal Fabrication with No Limits

All-in-one tube processing technology and automated fiber laser cutting systems from BLM Group provide the flexibility to do work ranging from furniture, job shop, motorcycle and hydraulic pipe construction to automotive, aerospace, agricultural and recreational equipment.

New Circular Saw Blades Enter the Market

Semi-finished or fully-finished HSS circular saw blades from Azak Tool are made from high quality 1.3343 DIN grade raw material using the latest process technologies in heat treatment, grinding, toothing, coating, testing and inspection.

FABTECH 2019: Finishing

Here are some of the finishing tools, systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.