Milling Machines

Filter by Process Zone:

Asymmetric XY Stages With Nanometer-Level Precision

ALIO introduces a positioning solution that provides customers with the exact X and Y travel ranges needed for their applications.

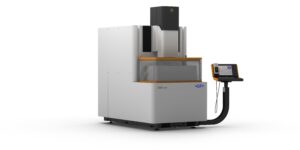

Servo Drive Triples Milling Rates

Equipped with servos for the X, Y, and Z axes, Tormach’s 1100MX is up to three times faster than the company’s 1100M and 770M mills. The machine delivers speeds of up to 10,000 rpm.

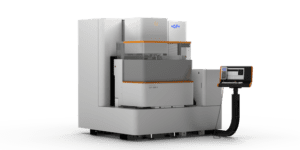

5-Axis Milling Machine Simplifies Complex Cutting Tasks

MC Machinery’s Eagle V5 can perform high-precision cuts with the X, Y, Z, B, and C axes moving simultaneously. Integrated 4/5-axis system allows X, Y, and Z travels of 21.6 in, 15.7 in, and 15.7 in, respectively.

Laser Deposition Welding Combined with 5-Axis Milling for Large Parts

A new machine size in powder nozzle technology, DMG MORI’s Lasertec 3D hybrid is designed for the additive manufacture of complex prototypes and small series parts as well as component repair and coating. It enables additive manufacturing and CNC milling on one machine – for 3D components in finished part quality.

Automatic Tool Changer for Dual-Drive Press Brakes

The automatic tool changer (ATC) for the BH series of dual-drive press brakes from MC Machinery Systems is designed for high-mix, low-volume environments by allowing for the greatest tooling variation on the market and facilitating operation by employees of all skill levels.

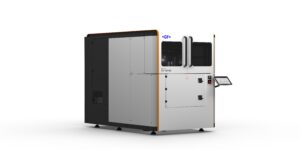

3D Metal Printer Is 40% Faster Than Predecessor

The DMP Flex 350 from GF Machining Solutions is the successor to 3D Systems’ ProX DMP 320 3D metal printer. Consistent repeatability is achieved with its pure, low-oxygen environment during printing.

KV Tooling Wins First Place in ANCA’s Tool of the Year Competition

Entries were judged on surface finish, specified nominal tolerance, tightest tolerance, and level of complexity.

SMART Wire Technology for AgieCharmilles CUT P Series

Thanks to radio frequency identification (RFID) technology, AgieCharmilles CUT P operators will never run out of wire because they’ll know the available length of each SMART wire spool. Spools also check selected wire technology and adjust machine performance accordingly to optimize cutting.

Die-Sinking EDM with Part- and Electrode-Changing Robot

The AgieCharmilles FORM X 400 with System 3R WorkPartner 1+ from GF Machining Solutions speeds output by bringing all production technologies together in one process chain. Users also benefit from the updated control interface’s advanced levels of logic, speed, and safety.

Automation-Ready EDM Speeds Up Additive Part Separation While Preserving Part Integrity

By blending horizontal wire orientation, a rotary axis, and an integrated basket to catch separated parts, the AgieCharmilles CUT AM 500 from GF Machining Solutions facilitates additive manufacturing (AM). The combination of features supports the part, allows for easy part handling, prevents part damage, and offers full automation readiness.

Spark Track Technology Prevents Wire Breakage for Easy, Stable EDM Processes

Two integrated features enable the AgieCharmilles CUT 2000 X wire EDM to provide unmatched accuracy and flexibility: GF Machining Solutions’ Intelligent Spark Protection System (ISPS) averts wire breakage by automatically unifying discharge distribution and Integrated Vision Unit (IVU) Advance automatically corrects machining errors.

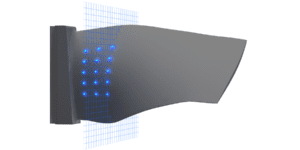

Automated Adaptive Milling

Automated adaptive blade milling from Liechti Engineering measures the workpiece in the machine and CAM software generates and optimizes a tool path that eliminates human error, optimizes productivity and ensures the highest quality result.