Multitasking Machines

Filter by Process Zone:

Tsugami/Rem Sales Appoints New VP

Craig Hahne is their new vice president of business development.

Hybrid Systems Finish 3D Printed Parts in Single Setups

Hybrid multi-tasking technologies from Mazak combine both additive and conventional subtractive processes to eliminate work-in-process, reduce lead times, improve part accuracy, shorten setup times and streamline processes.

The Power of Additive Machining

The Additive Machining module in Edgecam 2019 R1 software from Vero accurately guides a laser as it deposits material to build a shape using direct energy deposition, then uses advanced rotary and five-axis milling cycles to finish the final shape.

New Distributor for Mazak

Knox Machinery will represent them in southern Ohio.

Turning the Corner on Demanding Precision Jobs

Methods Machine Tools offers the Nakamura-Tome SC-300IIMYB multitasking turning center for machining difficult, high-hardness materials with extremely high accuracy, the Tornos Multi-Swiss 8×26 automatic lathe and the Tornos SwissNano for very high precision machining of complex small parts.

Multi-Tasking Mania: The Vanishing Single-Function Machine

Multitasking can deliver considerable savings, particularly on complex work that is highly profitable, by completing a part in one cycle and dramatically reducing setup and other non-value-added time, preventing opportunities for error and eliminating work-in-process inventory that might otherwise lay idle between standalone machine tools.

Complex Micro-Manufacturing with Multi-Tasking Machining

To cost-effectively meet the increasing demand for complex micro-size parts made of hard materials, the Bumotec s191FTLR 7-axis turn-mill from Starrag combines grinding, milling, turning, drilling and polishing processes without interruption.

Multi-Tasking Machining Reduces Lot Sizes of Complex Part Production

For six-sided complete machining of complex parts in volumes from one to 100,000, highly flexible Stama MT 733 series vertical spindle mill-turn centers from Chiron achieve process stability that can further reduce lot sizes through certainty the first part produced is usable.

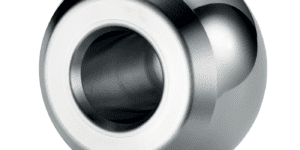

Multi-Tasking Machining of Complex Geometries in Hard Solid Materials

For small batch size production of automotive parts, fittings, pneumatics, hydraulics and other precision parts, PC multi-spindle automatics from Schütte deliver turning, tapping, mill cutting, polygon cutting, eccentric drilling and rear-side machining operations in one setup.

Large Format Multi-Tasking: 3D Metal Printing with Hybrid Machining

The LENS Controlled Atmosphere Hybrid System from Optomec supports building, repairing, coating and finishing of metal parts up to 860 mm in size with 5-axis strategies that combine additive and subtractive operations in a single tool path.

Lights-Out Multi-Tasking with 5-Axis Hybrid Machining/Grinding

Vertex Hybrid G 5-axis vertical machining/grinding centers from Mitsui Seiki provide CMM-level precision in critical high speed milling and grinding applications for lights-out machining of die and mold, optical and tooling components.

Multiple Machining Processes Complete Complex Parts in One Operation

The MS40-8 multi-spindle automatic lathe from INDEX performs off-center drilling, thread cutting, inclined drilling, cross drilling, contour milling, hobbing, bevel gear cutting, multi-edge turning and more to completely process even very complex automotive, fastener, connector and aerospace parts in one setup.