Plasma Cutting Systems

Filter by Process Zone:

Cincinnati Incorporated Receives Awards

They are selected as both “Best Place to Work” and “Best Workplace in Ohio.”

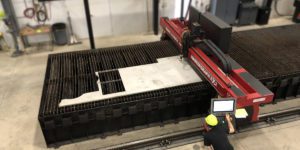

Penn Stainless Installs New Plasma Cutter

The Koike Aronson Versagraph Millennium Series 6300 system in their Jackson Center shop reduces lead times for deliveries in western Pennsylvania and eastern Ohio.

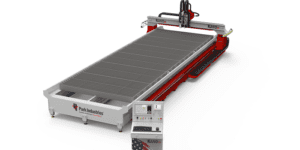

High Production, Precision Plasma Cutting of Construction Parts

Configured with a Hypertherm EDGE Connect CNC and high definition plasma system, and an oxy-fuel cutting torch, the KANO HD CNC plasma cutting machine from Park Industries is built on a unitized, precision machined, heavy duty steel base with cutting table styles and sizes available in 6 ft, 8 ft and 10 ft widths and 12 ft or 24 ft lengths.

Hypertherm Celebrates Milestone of Community Service

They reach 150,000 hours of volunteer work at the Hixon House shelter run by nonprofit Upper Valley Haven.

Park Industries Expands Capacity

They have recently completed a 42,460 sq ft addition and increased their manufacturing capacity by 20 percent.

Hypertherm Shares Record CSR Results

They hit records in all social areas, including their community engagement, environmental impact, and Associate well-being.

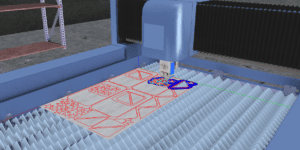

The Heat is On

To select the best sheet metal strategy and cutting order, users of this 3D simulation software can calculate graphically and interactively how heat sources affect sheet metal during the laser or plasma cutting process.

Schools Receive Grant from Hypertherm

Ten schools won the Spark Something Great Educational Grant and will receive a Powermax45 XP plasma system, a curriculum kit and in-person training.

Hypertherm Receives Recognition

Forbes honors them as one of the 500 Best Midsize Employers in America.

G & W Machinery Hires New Regional Sales Manager

Scott Grindstaff now handles equipment sales throughout Kentucky and sections of Southwestern Ohio.

Hypertherm Accepts Educational Grant Applications

Their Spark Something Great program enters its fourth year in supporting the next generation of welders and metal fabricators in plasma cutting.

How to Put Seeming Waste to Good Use

Coal-fired power plants are turning to ash removal conveyors that eliminate the need and use of ash ponds and support EPA regulations on the safe disposal of coal ash in landfills and surface impoundments. This job shop fabricated five of these large, sophisticated submerged scrapper conveyor systems, which one power plant now uses to recycle coal ash, conserve natural resources and save energy.