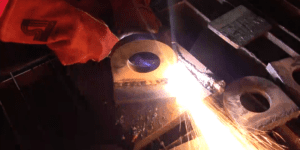

Plasma Cutting Systems

Filter by Process Zone:

Hypertherm Releases New CSR Report

They achieve record results in all areas of community engagement, environmental impact, and associate well-being.

Fast Plasma Cutting for the Small Shop

Torchmate 4400|4800 CNC plasma cutting systems from Lincoln Electric deliver faster cut speeds, consumable cost savings and exceptional repeatability, with less dross and better edge quality that reduces post-process operations.

Plasma Cutter Provides Highest Power-to-Weight Ratio and High Visibility Display

The Thermal Dynamics Cutmaster 60i handheld air plasma cutting system from ESAB is ideal for small shops and garages, general manufacturing to mobile fabrication, farm/ranch, construction, maintenance and repair, automotive bodies and frames, HVAC and training facilities.

High Speed Plasma Cutting System Slashes Operating Costs

The Hypertherm XPR300 plasma cutting system on the PlasMAX high speed cutting machine from Controlled Automation increases cut speed, dramatically improves productivity, triples realized consumable life in many applications, and slashes operating costs by over 50 percent.

Rebuilding American Manufacturing, One Veteran at a Time

A perfect storm: One million veterans leave the service every five years as a projected two million manufacturing jobs go unfilled in the U.S. over the next decade due to lack of skilled labor. Take a closer look at how veterans are forging new careers in metalworking through Workshops for Warriors – and how manufacturers can put skin in the game with support.

Approaching Removal Jobs from a New Angle

Efficient attachment removal has always been tricky. Without the ability to mechanically position the tool so that a closer cut can be achieved with less residual metal, workers were forced to deal with the drawbacks of traditional removal processes. But not anymore: A small alteration has made a huge impact on the attachment removal process.

Hypertherm Continues Support for Schools in North America

Their 2017 Spark Something Great Educational Grant gets the latest plasma technology into schools to train the next generation of metalworkers.

Plasma Beam Profiler Cuts Both Bolted and Welded Connections

From 3D profiling to beam coping, the new Robotic Profile Cutting Line RPC 2.0 from HGG is ideal for cutting I/H beams and square/rectangular tubing profiles used in offshore or steel construction applications.

Air Plasma System Consumables Reduce Secondary Grinding by Cutting Closer

FlushCut consumables for Powermax105 and Powermax125 air plasma systems from Hypertherm enable users to cut closer to the base metal than ever before, reducing grinding work and increasing the reuse of lugs and attachments.

Educational Grants for North American Schools from Hypertherm

Ten schools will be awarded new Powermax45 XP plasma cutting and gouging systems, along with full plasma cutting curriculum kits.

Hypertherm Expands Volunteer Program

Their associates get an additional eight hours of paid time off each year to volunteer in community activities.

FABTECH 2016: Forming & Fabricating (Part Two)

Take a closer look at some of the metal forming and fabrication technologies that will be exhibited November 16-18 on the show floor in Las Vegas.