Power Sources

Filter by Process Zone:

Digital Controls Improve Submerged Arc Welding Performance

The SubArc Digital Series from Miller Electric makes setup and operation easier and ensures continuous delivery of flux to the arc.

The Pride of the Pipeline

By changing welding processes, this oil and gas production equipment manufacturer cut more than 200 man-hours out of each product to thrive during the shale gas boom.

How Electronic Fuel Injection Technology Improves Efficiency of Engine-Driven Welding Power Sources

As contractors and welders continually look for ways to reduce welding costs and be more efficient, things as simple as engine choice can make quite a difference.

Lincoln Electric Introduces Fuel-Saving Option on its Ranger 305 G Multi-Process Welder/Generator

Lincoln Electric‘s K3928-1 Ranger 305 G EFI combines a powerful multi-process, engine-driven welder with a Kohler 25-hp electronic-fuel-injection (EFI) engine.

Advanced Welding System Expands Capabilities for Manufacturers

The Power Wave® Advanced Module from Lincoln Electric performs shielded metal arc, MIG, pulsed MIG, TIG and Surface Tension Transfer® welding that can help weld open root gaps with high frequency inverter technology.

Rechargable Welding System Lets Users Make High-Quality Welds Anywhere

The Fronius AccuPocket combines the mobility welding technicians have been seeking with the reliable power, quality control and battery technology the job demands.

Field of Dreams

Take a look at how this Wisconsin fabricator uses the portable all-in-one Multimatic 200 multiprocess power source from Miller Electric to gain versatility and increase their welding productivity by 25 to 30 percent on field repair and fabrication jobs.

Simplified Multiprocess Welding Capabilities for On-Site Pipe Welding Applications

This welding system from Miller Electric brings proven PipeWorx pipe welding processes to portable field applications in the refinery, petrochemical, power generation and HVAC industries to improve productivity, uptime and quality.

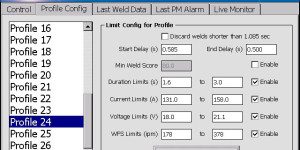

MOTOMAN INTERFACE FOR LINCOLN ELECTRIC POWER WAVE POWER SOURCES

Users can now program weld parameters as work point/trim or amps/volts, along with up to four “Wave Controls” with allowable limits displayed from the process library in the Lincoln power source. Users can also program Lincoln’s Production Monitoring™ process limits and define alarm and fault conditions from the robot’s touch screen pendant display.

Field of Dreams

Take a look at how Wisconsin fabricator High Tech Welding uses a portable all-in-one multiprocess power source to gain versatility and increase their welding productivity by 25 to 30 percent on field repair and fabrication jobs.

Power Sources

A welding power supply provides an electric current for welding. A constant current (CC) machine varies output voltage to maintain a steady current, while a constant voltage (CV) machine fluctuates output current to maintain a set voltage. Shielded metal arc…

Estimating Total Welding Costs

Keeping your welding costs low goes far beyond buying the lowest priced wire available. You must analyze how welding processes that increase deposition rate and increase productivity will reduce the largest component of welding costs – your labor and overhead. Here’s how to do it.