Press Brakes, Panel Benders

Filter by Process Zone:

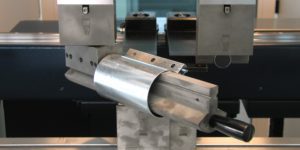

Quick, Accurate Rolling of Medium to Heavy Flat, Angle, Pipe, Tube and Channel Sections

Connected to an ironworker using a Hydraulic Accessory Pack or Porta Power, the RRM2 Radius Roller from Edwards Manufacturing quickly changes from vertical orientation for smaller projects to horizontal for larger, heavier jobs.

New Fiber Laser and Portable Electric Press Brake

The 40 ton GOFORM portable electric press brake from Cincinnati Incorporated uses a 6-axis back gauge that is equipped with HMI control.

Closing the Loop: Strategies for Bending Closed Forms

With a bit of creativity and thought to overcome limitations, it is often possible to form closed profiles and other difficult parts with a standard press brake. Here are some tips on how to do it.

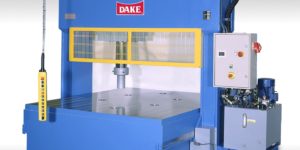

Heavy Duty Moveable Frame Press for Straightening Applications

The PMM 200MD Movable Frame Press from Dake is ideal for assembly work and straightening applications.

Electric Press Brake Efficiently Forms Parts at High Bending Speeds

Using a precision 4-axis back gauge with a fast acting ram and higher bending force, the Dyna-Press 40/15 Plus from LVD Strippit produces extremely consistent, repeatable and accurate parts at a lower cost.

LVD Strippit Opens Midwest Support Center

The Minnesota facility is the first of three U.S. regional support centers that will open in 2016.

A Little TLC Means a Lot to Press Brake Tooling

Press brake tools are the only parts of the machine that ever touch the finished parts being formed. The best precision CNC press brake cannot produce good products with poor tooling, and bad tooling makes all the good hardware in the process – including the machine operator – useless.

Panel Bending Redefined

The TruBend Center 5030 panel bending machine from TRUMPF handles 10 ft long aluminum and mild steel sheets up to 0.120 in thick and stainless steel sheets up to 0.090 in thick.

The Next Push in High Speed Bending

Take a look at how press brake automation continues to optimize the bending process and integrate with other downstream operations from a high speed laser cutting system to transform the “push” demands of the fabricating process into a competitive advantage for your shop.

Active Crowning Improves Part Accuracy

This patented ACSG active crowning technology can solve unpredictable press brake forming issues with sheet metal during fabrication.

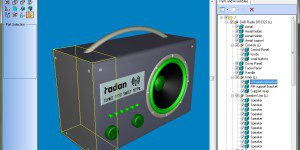

CAD/CAM Integrated Press Brake Software

Radbend 2016 press brake software closely links CAD/CAM, Radbend, Radm-ax and Radtube functions with a new style of program and file-type icons for a more unified feel.

Panel Bending Redefined

This panel bending technology produces positive and negative bends, folds and circular bends with a variety of radii for a significant advantage which reduces set up times and tooling costs.