Press Brakes, Panel Benders

Filter by Process Zone:

Betenbender Manufacturing, Inc.

An overview of the company and its organization, products, services and capabilities.

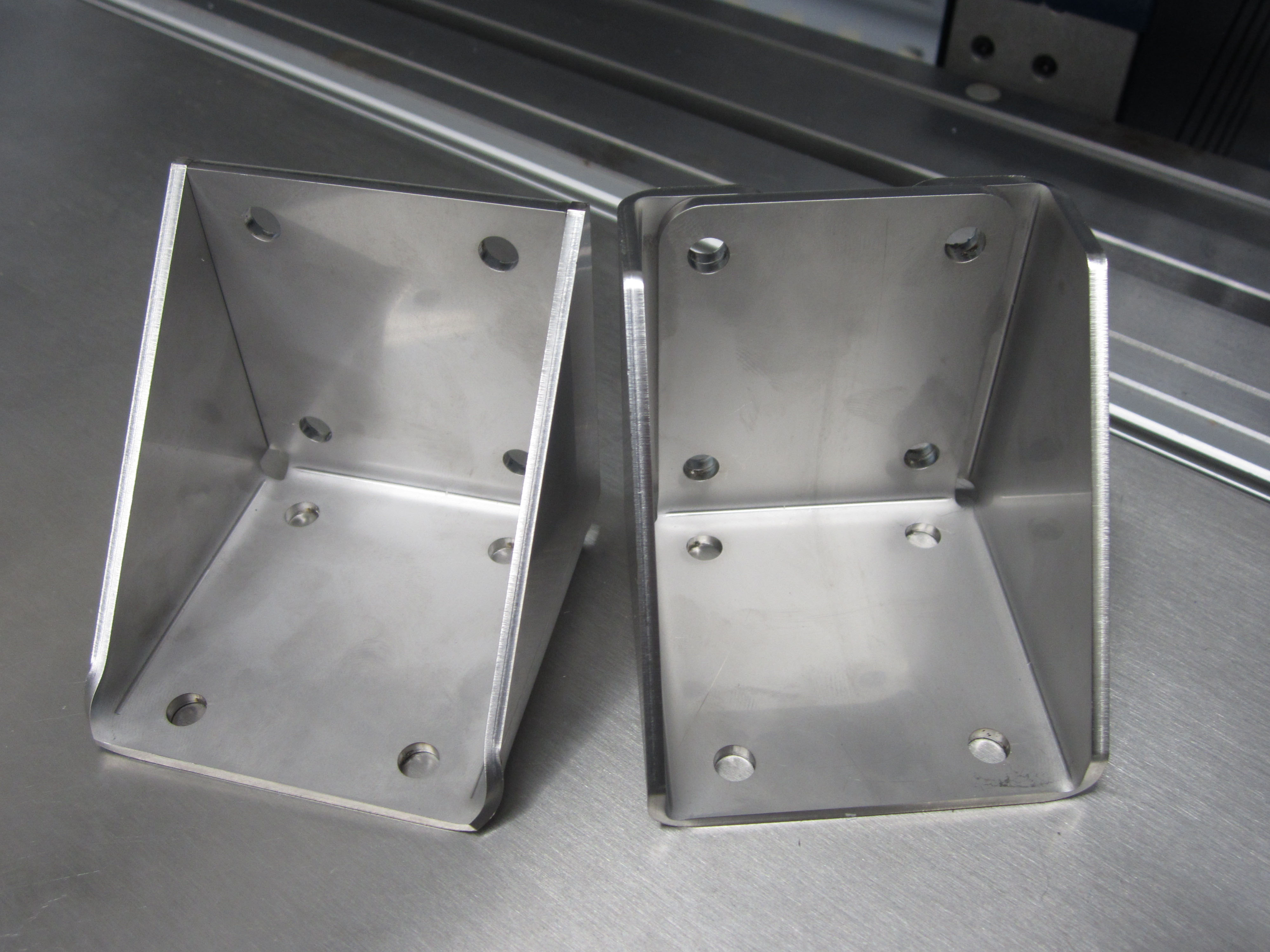

Rethinking Parts In Sheet Metal Design: The Angle Bracket

Revisiting the steps used to make a common bracket can eliminate the need for welding, make the part even easier to produce, and demonstrate how the smallest improvements in part design can reap major benefits in time and money.

Bending Aesthetics: When the Finish Comes First

Sometimes marks caused by the lower die during the bending process can turn a good part into scrap metal, even if the scrapes are very light and have no functional bearing on the part whatsoever. To deal with this problem, it is necessary to reduce or eliminate the movement of the material over the hard shoulders of the die. Here are several ways to do this.

Advances in Press Brake Technology

A review of the latest press brake systems and robot automation from Wolf Robotics, LVD Strippit, Amada America, Betenbender and TRUMPF that can help you reduce your metal forming costs and reduce your operating cycle times.

Automation Improves Press Brake Profitability

Robotic press brakes offer higher productivity, more flexibility and better profitability for the fabricator. Standard robotic press brake systems from Wolf Robotics include all components, less the press brake, to accommodate common sizes and weights of typical parts. Most press brake equipment is capable of integration into Wolf standard cells.

CHECK-UP ON PREVENTIVE MAINTENANCE FOR HYDRAULIC PRESSES

Guest columnists Thomas Lavoie and Carl Jean of Greenerd Press & Machine Company explain how, by knowing when a hydraulic press is running well or is in need of attention, and by consistently conducting preventative maintenance, the lifespan of a press can be significantly increased to maximize your investment.