Punches and Dies

Filter by Process Zone:

Powerfully Simple, Simply Powerful: GibbsCAM 2024

GibbsCAM announces the release of GibbsCAM 2024, which continues to boost end-user productivity for programming advanced machining centers, underpinning the GibbsCAM promise of Powerfully Simple, Simply Powerful.

FABTECH 2023-“Driving Manufacturing Forward”

FABTECH Heads to Chicago’s McCormick Place from September 11-14!

New One-Hit-Hinge™ Tool Reduces Hits and Part Costs vs. Traditional Methods

Since the One-Hit-Hinge does not have to be formed straight up and curled down (3-hi style), the hinge diameter can be larger and will not interfere with the machine gap.

Tooling Tech Group Announces Director of Sales for Stamping Division

Tooling Tech Group (Macomb, MI) has hired Kevin Kowalski as the director of sales for its stamping and die division.

Device Protects Ball Bearing Retainer Cages

Throw out your rubber bands and twist-wire! Superior Die Set’s Cage Saver retracts ball bearing retainer cages during die-handling and maintenance and protects the assembly from water and detergent during pressure washing.

Automatic Ball Cage Punching Machine Increases Output By More Than 40%

Powered by a servo drive instead of a flywheel, Karl Klink’s RT-HLKK1000 ball cage punching machine improves cut quality by increasing cutting speed. Two die stations and streamlined retooling process also help shorten cycle times from 10 to 7 seconds.

Mate’s Name Change Points To Entry Into Machining

Under its new corporate name, Mate Precision Technologies looks toward expansion into precision machining. Watch for a major new product release arriving in 2021.

Multicyl’s Protocol Takes Aim at COVID-19

The company remains open and has put mandatory measures in place for employees and visitors to help prevent the spread of the virus. The No. 1 rule directs staff to wash hands for 20 seconds upon arriving to work and after handling incoming or shared material.

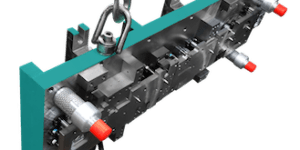

Ease and Adjustability for Punching Applications

Multicyl’s Press in a Box and MultiPunch Linear Rail work together to add versatility to tooling applications and press solutions.

Tooling Tech Group Announces Completion of TTG Automation Expansion

Addition brings Michigan facility size to 59,000 square feet.

Roll-Kraft Expands Sales Team

They hire Sean Larkin as a technical performance specialist.

How to Increase Productivity and Efficiency in Production Stamping

The Fibro Electronic Tapping Unit and the Wireless Pressure Monitoring from Fibro enables production stampers to add value, increase throughput and improve operational efficiency.