Punches and Dies

Filter by Process Zone:

Using Advanced CAD/CAM to Optimize Machining of Complex, Progressive Stamping Dies

Stamping dies feature complex geometries with tight tolerances that can take time to produce due to tooling changes, breakages, or programming challenges. This machine shop shares some insights on how they use powerful CAD/CAM software for easier and more functional programming that minimizes time and costs.

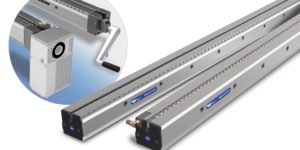

Press Brake Tooling for Easier, Safer Punch Front Loading

The Maglock Magnetic Safety System of punches and dies from Mate Precision Tooling always results in the shoulder seating onto the holder with a strong, yet balanced connection that also makes lateral (left or right) position adjustments easy.

How the Stamping Industry Stays Strong

The stamping industry will be alive and strong in 2018, shifting to meet the changing needs of the marketplace and their customers. Here are some insights into how the industry is evolving to remain competitive and healthy.

Hoffman Group Recognized as Key Automotive Supplier

Brose honors them for outstanding tool quality, cost, on-time delivery and innovation.

Wila USA Names New Business Development Manager

Steve Westbrook now handles sales and support in Texas, Oklahoma, Arkansas, Louisiana, and Mississippi.

Mitchell Metal Products Wins Award

They receive the first National Reshoring Award for their efforts in bringing manufacturing back home to the United States.

AHB Tooling & Machinery Acquires Division of Westbrook Engineering

Adding the new machinery sales division reinforces their position as a full-service metalworking distributor.

No Marks Allowed

Precision-made tooling is part of the formula that helps this Nashville shop produce unmarked, repeatable and high quality stainless parts that meet both cosmetic appearance and food safety standards.

High and Low Capacity Die Carts and Work Stands

The Mini-Titan low capacity standard die cart line from Green Valley Manufacturing has a 250 lb to 2,000 lb capacity range, and their newly designed work stands from the ever-expanding Heavy Duty Titan Industrial Work Horse line has capacities of 500 lb per pair to 100,000 lb per pair.

Automated Storage & Retrieval Systems for Efficient Handling of Heavy Dies

Ideal for press rooms with limited space that continuously move a high volume of heavy dies in and out of storage, automated systems from Atlas Technologies are fully programmable and interface with other handling equipment to create a custom storage system that is specific to a facility’s needs.

Press Brake and Turret Punch Tooling Increases Efficiency, Reduces Errors and Costs

To gain efficiency, reduce errors and lower operating costs, Wilson Tool offers the Express Crowning System and rotary bend tooling for press brakes, iSeries AITS thick turret tooling and the QuickTap tapping tool for turret presses, and the fully automated XSharp grinder.

Factory Automation and Tool and Die Systems

DT Engineering builds factory automation systems, tool and die systems, and designs and produces stamping dies, including Class A/B dies, draw dies, single hit dies, trim dies, transfer dies, form dies, progressive dies and cam dies.