Ram EDM Machines

Filter by Process Zone:

What’s New in EDM

A review of some of the latest EDM systems now on the market.

Innovative EDM Technologies

The VZ500LH Wire EDM is ideal for extreme height applications in mold and die, aerospace and energy jobs — one of several of the latest advanced EDM solutions from Sodick.

Medical Machining Applications and More

GF Machining Solutions offers the AgieCharmilles CUT 20 P wire and FORM 20iRTC sinker EDMs for precision, performance and efficiency in medical machining.

Advanced EDM Capabilities

This advanced equipment from Makino is ideal for aerospace manufacturers needing to produce a wide range of hole shapes and sizes within a single setup, significantly reducing required tool variety and overall cycle times.

Absolute Machine Tools Adds EDM Consumables Division

AccuteX EDM carries consumables for its own machines along with Mitsubishi, Sodick, FANUC, and other OEMs.

Adams Machinery Now Reps for GF Machining Solutions

The company now sells their EDM consumables throughout Arizona, New Mexico, and parts of Nevada.

IMTS 2014: EDM

Here is proven, reliable, high-accuracy technology for those in the tool and die industry, especially shops that specialize in one-off or specialty components and need everything from CNC wire EDM equipment to die sinking machines.

Heavy-Duty Die Sinker EDM for High Accuracy Machining

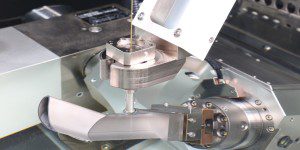

The Accutex DS-550CM Die Sinker EDM from Absolute Machine Tools includes a built-in C axis with 360 deg indexing, an automatic electrode changer, dielectric cooler, and custom tooling package.

A Hole New Game: Precision EDM Holemaking Goes Smaller, Deeper and Faster

While hole-popper systems are quite capable of generating very small accurate holes with good surface quality, advanced EDM drilling systems dramatically increase a shop’s capability to consistently produce tiny holes that are even more accurate and with higher quality.

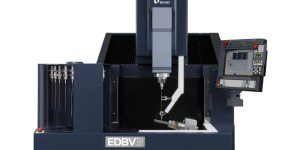

Ram EDM Machines

Ram electrical discharge machining (EDM), also known as die sinking, uses an electrode typically pre-machined to a specified shape from graphite or copper that is sunk into a workpiece submerged in a dielectric fluid, leaving a negative imprint. A controlled…

Liquid-Cooled Generator Technology Reduces EDM Electrode Wear

A breakthrough liquid-cooled generator technology marks the next generation of CNC Die Sinking that has revolutionized the way machine tool builders look at their power supplies.

Major Tool & Machine Adds Large Part Production Capacity

The 500,000 sq ft climate-controlled campus is scheduled to be completed in 2015.