Robotics / Automation

Filter by Process Zone:

How Robotics Can Offset Trade Cost Hikes

To offset the rising cost of metals and avoid hurting their bottom lines, many shops are turning to robotics for repetitive-based processes to help optimize their workforce productivity through precision and consistency.

Embracing the Robotic Revolution

U.S. manufacturers cannot ignore the growing implications of failing to adopt modern robotics and automated technologies. Rather than fearing the rise of the robot, Americans must further embrace the technology or risk getting left behind in the global manufacturing race.

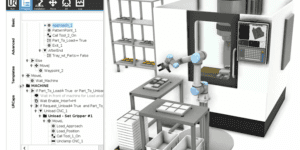

Fast and Easy Robot Cell Configuration and Deployment

Application Builder from Universal Robots walks users through the entire process of building a successful machine tending, assembly or packaging application with step-by-step guidance on end effectors, programming, machine interfaces and more that is optimized for throughput and cost.

Plug-and-Play End-of-Arm Vacuum Tooling for Cobots Improves Productivity

The flexible piCOBOT end-of-arm-tool from Piab is designed for maximum flexibility and reach with 3.8 in to 5.6 in wide, ±15 deg tiltable gripper arms that can be fitted with two suction cups. Alternatively, the gripper can be replaced by a single suction cup mount directly on the cobot’s pump unit.

Intuitive Cobot Automates Repetitive Tasks

The advanced TM Series Collaborative Robot from Omron boosts production and reduces employee fatigue by safely automating most repetitive production tasks, such as machine tending, loading and unloading, assembly, screw driving, gluing, testing or soldering.

Larger, Stronger and Safe Mobile Robots for Leaner Production

The powerful, robust MiR500 mobile robot from Mobile Industrial Robots autonomously picks up, transports and unloads heavy loads and can be equipped with pallet forks, conveyors, a robot arm or other options to support a wide range of applications.

Cost Effective Robots for Part Inspection, Pick and Place

The KMXL Cartesian multi-axis robot from Hiwin is quickly and easily configured for high accuracy and repeatability in specific pick and place or part inspection applications.

Smart Robotic Part Sorting and Arranging Made Easy

SmartWing robots from Fuji make workpiece sorting, accurate long screw placing, loose part sorting and arranging, and dual robot cooperation for inserting and tightening screws remarkably easy and efficient with accessible automation that virtually eliminates teaching.

Doing Tasks with Robots That Were Not Possible Before

The intuitive Force Guide integrated force control system from Epson Robots enables robots to perform grinding, polishing, part insertion, screw driving and other high precision operations that require high performance motion guidance.

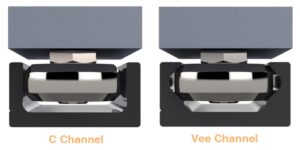

Hybrid Wheel Plate for Automated Machine Loading

The flexible UtiliTrak VC wheel plate from Bishop-Wisecarver combines low rolling friction with high speed capacity for automated machine loading applications that can make machining operations more efficient.

Effective Measurement and Control of Shop Tooling

The Smile universal presetting and measuring machine from Zoller accurately measures standard tools easily and quickly, while their Smart Cabinets precisely track the exact location of any given tool, who checked the tool out, for which machine and to which job.

Automated Sawing and Storage System Converts Bottleneck into Capacity

Hydraulic cylinder manufacturer AHP Merkle quadrupled their throughput by integrating a CNC circular sawing machine, tower storage system and robot-assisted sorting system from KASTO to shorten delivery times on a wide range of high quality cylinders.