Robotics / Automation

Filter by Process Zone:

Award-Winning Safeguarding Solution for Industrial Robots Lowers Collaboration Costs

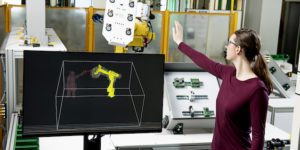

Veo Robotics’ FreeMove sensors-and-software system uses advanced computer vision and 3D sensing to safely turn a high-speed, heavy-load industrial robot arm into a collaborative robot (cobot) that’s faster – and thus more productive – than traditional cobots.

High-Speed Cobot Ensures Safety Without Compromising Productivity

Designed to support intermittent interaction between human and industrial robot, ABB Robotics’ 1100 Swifti CRB (for “collaborative robot”) automatically slows, stops, and restarts depending on an employee’s presence in preprogrammed safety zones.

World’s Most Powerful Vacuum Gripper Cost-Effectively Lifts Heavy Loads

Capable of lifting 44 pounds (20 kg), OnRobot’s electrically powered VGP20 vacuum gripper performs the same heavy-duty tasks as a pneumatic gripper for a fraction of the cost and complexity. Compatible with all major robot brands.

Cleanroom-Ready Gripper for Demanding Applications

OnRobot’s IP67-certified, collaborative 2FG7 parallel gripper is the latest addition to OnRobot’s range of no-fuss, all-electric gripper products. Deployed within minutes, it’s designed to handle demanding payloads, even where space is tight.

Three Cobots with Built-In Vision Systems

Delivering payloads ranging from 9 to 31 pounds and reach up to 4.25 feet, the TM5, TM12, and TM14 cobots from Techman Robot can “see” and automatically reposition objects using a smart user interface.

All-in-One Kits for Quality Assurance Using Universal Robots’ UR3e Cobot

Designed for Universal Robots’ UR3e cobot arm, the Q-Span Workstation from New Scale Robotics comes with everything necessary to automate small-part measurement inspection. You can improve gage R&R and boost capacity without adding headcount.

Two-Arm Cobot Doubles Efficiency Without Sacrificing Safety

Even though they have two arms, Kawasaki Robotics’ duAro cobots fit into a single-person space while providing enough room for an employee to safely work alongside. Two models provide 8.8- and 13-pound payloads.

Three Updated Cobot Models Offer Greater Connectivity

The “A” in Hanwha’s HCR-3A, HCR-5A, and HCR-12A stands for “advanced.” Three cobot models improve on their predecessors by offering customizable solution packages that incorporate artificial intelligence and mobility technologies.

Handling Robot for Hazardous Environments

Yaskawa Motoman’s explosion-proof MHP45L handling robot easily moves 100-pound workpieces without interfering with peripheral equipment in a booth, streamlining automated paint line layouts by eliminating the need for dedicated part transfer.

Expand Your Robot’s Utility by Adding a 7th Axis

Igus all-in-one linear actuator adapter kits contain everything necessary to enable a robot to move vertically, horizontally, or overhead. Kits are available for Universal Robots and Robolink robots.

Small-Footprint Part Loader Increases CNC Machine Productivity

Offering a payload of 26.45 pounds each, Halter CNC Automation’s three Compact robot models save on factory floor space, making it easier for manufacturers to automate part loading and unloading of lathes and mills.

Robot-Based Press-Automation Solution

ABB Robotics’ IRB 760PT is the basis of two configurations – the FX and the TRX – that optimize speed and minimize die interference in press-tending applications. The robot provides a flexible automation solution that’s easily repurposed to handle changing requirements.