Software

Filter by Process Zone:

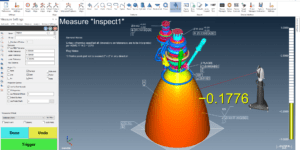

Verisurf Software 2022 Release Includes MBD for Polygonal Meshes

Verisurf 2022 supports Model-Based Definition (MBD) for polygonal meshes, enabling users to create and inspect using intelligent meshes.

Take Advantage of Short Cycle Times and Accurate, High-Precision Machining

Progressive and innovative metal-cutting machines and software speed up your processes by reducing cycle time and enhancing productivity.

Seco Tool’s Machine Monitoring Maximizes Manufacturing Efficiency

Software monitors production data on a continuous basis to build a full picture of what happens on a manufacturer’s shop floor and beyond.

Siemens New SINUMERIK CNC is a Digital Native Machine Tool Control

Mapping the development process with SINUMERIK ONE reduces product development and time-to-market. SINUMERIK ONE marks the beginning of a new era. The CNC system is revolutionizing everything that has existed so far. All it takes is a small spark to set great things in motion. Maximize your productivity, innovate faster, excite digitalization, and discover a new way of thinking.

Set Your Gears in Motion

Metal fabrication shops benefit from the advances developed by manufacturers and service providers to increase operational efficiencies.

Caron Engineering’s New Signature Analysis for CNC Machining

This capability is specifically beneficial for constant surface speed cutting operations, which are difficult to monitor due to the varying spindle RPM as material is removed.

Yaskawa’s Smart Pendant Software Version 2.1 Expands Ease of Use

Smart Pendant v2.1 is well-suited for quick robotic implementation of basic assembly, injection molding, inspection, machine tending, material handling, and pick and place tasks.

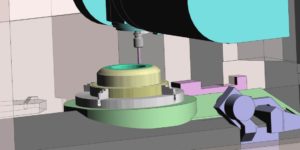

Hexagon’s Advanced CAD/CAM Software

EDGECAM 2022 anticipates future capabilities for milling and turning; WORKNC software introduces ‘manufacturing aware’ CAD for mold and die makers .

Beckhoff Automation’s TwinCAT 3 Directly Integrates OPC UA Publisher/Subscriber

Beckhoff provides real time capable data communication via OPC UA with the new TF6105 function in its universal automation software.

Five Ways Oil and Gas Companies Can Maximize the Efficiency of Critical Component Production

Industry 4.0 advancements increase productivity and performance by reducing the margin of error, providing insights into your machining operation, and streamlining and simplifying essential processes.

Five Things You Need to Know About Connected Machine Monitoring

There are numerous advantages to implementing machine monitoring platforms. Start small and zero in on data that identifies pain points so your shop can make the changes needed to optimize goals.

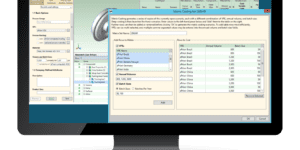

THE AUTOMATING OF COST ESTIMATES: aPriori and its Software

aPriori’s cost-estimating software can benefit

1. engineers designing parts,

2. companies outsourcing the manufacture of parts, and

3. contract manufacturers bidding on jobs. For all three types of users, the software offers quick, accurate, money-saving analysis.