Software

Filter by Process Zone:

Track and Control Stamping Operations in Real Time From Wherever You Are

IRMCO Advanced Metalforming Lubricant Technologies’ iNSIGHT enables metal stampers to track the rate of chemical consumption by part and process and compare the data to tool life to pinpoint the actual cost per part for each process in a facility.

Automated Centerless Tube Grinder

An automated version of Glebar’s TF-9BHD infeed/thrufeed centerless grinder, the TF-9D features the widest work wheel on the market. Customizable interface designed for automation and 8-5/8-inch-wide work wheel combine to increase throughput.

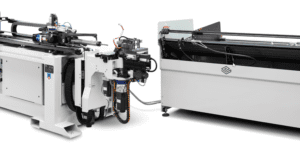

Autonomous Tube/Wire Bender Enables Lights-Out Production

Featuring a compact layout, integrated loading/unloading capability, and easy-to-use programming software, BLM Group’s Smart Bender enables an operator to go from design to part in one click and walk away.

Design the Ideal Floor Layout for Cobotic Production and/or Assembly

Delmia Robotics’ software from Dassault Systemes maximizes automation initiatives by enabling manufacturers to design and virtually test a drilling-and-riveting, arc welding, spot welding, and/or material handling line before rolling it out.

End-Effector Kits Increase Cobot Flexibility

Do you own a Fanuc CRX cobot? Thinking of buying one? ATI Industrial Automation’s end-effector kits make the most of your investment by enabling applications including deburring, orbital sanding, tool changing, and force/torque sensing.

Manufacturing Software is ‘Single Source of Truth’ For Product, Process, Quality

Siemens extends Xcelerator portfolio with enterprise-wide quality management system. Teamcenter Quality provides an all-geographies collaboration platform that also enables engineers to establish their own parameters for excellence.

How A Global Metal Fabricator Standardized Design and Manufacturing Processes

U.S.-based AGCO makes five brands of agricultural equipment at 40 plants on six continents. To bring order to the potential chaos of model-year changes and new product introductions, the company deployed software for a design anywhere, build anywhere strategy.

Design Is Destiny If You Want To Optimize Beveling

Even the most sophisticated nesting software won’t eliminate the need to manually finish an edge if the job’s not thought through from start to finish. Follow these three best practices to minimize wasted time and material.

Software Enables Both Additive And Subtractive Applications

When coupled with an MPiec controller, machine tool builders and experienced CNC programmers can use Yaskawa Compass graphical user software to design HMI hybrid machines as well as 3D printing, shape cutting, and robotics.

Quality Mass Production with Metal Binder Jetting IS Possible

Hexagon’s Simufact Additive powerful and scalable process simulation environment for first-time-right optimization of metal binder jetting (MBJ) predicts and automatically corrects for final distortion and residual stresses of 3D-printed parts.

Software Add-On Saves Time and Improves Consistency

DP Technology’s Esprit Additive for Powder Bed is compatible with any file supported by SolidWorks. The add-on application streamlines production by eliminating the need to repeatedly define manufacturing information.

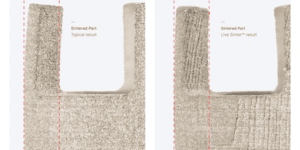

Simulation Software Takes Guesswork Out of 3D Metal Printing

Live Sinter enables inexperienced 3D-printer operators to consistently produce accurate parts using Desktop Metal’s Shop System and Production System machines. The software automatically overcorrects for the shrinkage and distortion inherent in sintering.