Software

Filter by Process Zone:

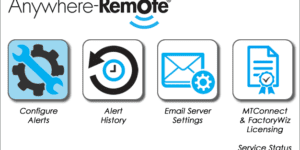

Live Machine Production Data Anywhere, Anytime Via Email to All Devices

Using FactoryWiz Monitoring and DNC, Anywhere-Remote for Kitamura machine tools boosts production by collecting live unbiased shop floor data, creating baseline metrics and identifying process improvement opportunities.

Three Major Tipping Points that are Pushing Shops into Industry 4.0

Here are three very big, very real factors that shops must embrace to compete in the fourth industrial revolution.

Acorns, User Experience and Optimization

With the advent of technologies like the iPad, the field of predictive maintenance has now become an accessible, cost effective and achievable goal for many companies, from small shops to large factories. They can base an entire predictive maintenance platform on the iPad and utilize technology that is constantly improving.

Mobile Monitoring and Maintenance of Fluids Used in the Machine Shop

Using the TechTool mobile app from Fluid Service Technologies on their iPhone or iPad, technicians can monitor fluid inventory, usage, waste and recycling on an unlimited number of machine tools.

Machine Monitoring and Real-Time Analytics Software

To bring Industrial IoT to the factory floor with software that’s simple to integrate and easy to use, this modern, secure cloud application from MachineMetrics easily integrates into precision CNC machine tools, Swiss, stamping, and die and mold shops.

Transform Mobile Devices into Virtual Operator Panels for Drive Control on Machine Tools

The Sinamics V20 Smart Access web server module from Siemens provides a Wi-Fi hot spot wireless connection that facilitates setup, programming, commissioning, production monitoring and maintenance on a variety of machine tools and production equipment.

Use iPad With Two-Axis Wireless Machine Level for Higher Precision

The two-axis Wireless Machine Level from GTI Predictive Technology simultaneously displays 2D plane angles to simplify and resolve the hurdles of taking angles one axis at a time and leveling machinery to 0.001 deg angular measurement accuracy.

Integrated Tool Tracking Manages All Tools and Equipment on the Jobsite

The TICK tracker from Milwaukee Tool easily attaches hidden from sight on any tool or piece of equipment and uses the ONE-KEY app to track anything in inventory, regardless of brand, saving fabricators time and money if a tool goes down or is needed on short notice.

Remote Diagnostics Monitor Machines, Reduce Downtime, Eliminate Unnecessary Costs

The TWConnect remote connectivity service from Taylor-Winfield simplifies off-site diagnostics and problem-solving by giving users immediate monitoring of data and diagnostics from geographically dispersed locations.

Mobile App for Metalworking Fluid Monitoring and Maintenance

Ideal for monitoring fluid inventory, usage, waste and recycling on everything from machine tool coolants and lubricants to parts washer degreasers, the TechTool mobile app from Fluid Service Technologies helps machine shops monitor an unlimited number of assets.

Advanced Analytics and Deep Learning in Condition-Based Maintenance

The FIELD system from FANUC provides intelligent condition-based maintenance to help optimize the performance and life of CNCs, robots, peripheral devices and sensors used in automation systems.

Optimize Machining/Grinding Cycles

The PowerReader from GTI Predictive Technology allows a shop to add more cycles to their existing machining work flow to make the most out of it, increasing output, saving time and money.