Stamping Presses

Filter by Process Zone:

AIDA-America Volunteers Help Areas Hit by Tornados

They help clean up efforts after 15 tornadoes hit the Miami Valley on Memorial Day.

Stamping AHSS Got You Down? Reconsider Your Tool Design

To reduce wear and tool breakage when forming or blanking AHSS material, here are some tips on revisiting the type of tool steel used, the design of the tool itself, and whether or not adding a coating or surface finish will improve performance and provide longer tool life.

Staff Promotions at AIDA-America

Bob Southwell, Mike West, Al Wichner and Ben Shepherd move into new responsibilities.

The Evolving Press Room

Hydraulic press technology and other advances in stamping presses, deep drawing operations, coil handling equipment, automation, press controls and monitoring are helping press rooms to deliver shorter runs of high-mix parts faster, more efficiently, and more profitably.

Top Ten Reasons to Go Hydraulic

To meet the growing demands for smaller lots and varied applications, hydraulic press technology is faster and more reliable than ever to improve press room productivity and the bottom line.

Smart In-Process Monitoring of Stamping and Forming Operations

Brankamp X7 “smart” in-process monitoring systems for cold and hot forming, thread rolling and stamping operations from Marposs use AI to quickly monitor machine setups and effectively control machine performance by detecting manufacturing faults, as well as part or tool variations.

Metal Stamping Press Automation Controller

To improve press room stamping operations, the SmartPAC PRO controller from Wintriss Controls enables networked users to share and view the entire contents of each programmed setup on a single screen in an Industry 4.0 environment.

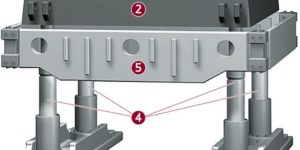

Modular Die Cushion System Extends the Life of Deep-Drawing Dies

The Modular Die Cushion System from Moog improves process reliability, reduces commissioning time, offers flexible layout options for integrating the manifold and requires comparatively little piping to help press rooms lower their maintenance and piping costs.

Beckwood Press to Build Huge Machine for Wabash National

The 3,500 ton hydraulic bulge forming press will be used to form stainless steel and aluminum tank heads with diameters up to 156 in for tanks and silos.

Advanced Gap Frame Stamping Presses

The NC1-800(2)E 80-ton mechanical gap frame press and the versatile DSF-C1-800 80-ton gap frame direct-drive servo press from AIDA-America provide tight precision and versatility for the most demanding stamping operations.

AIDA-America Names New President & COO

Takeshi Nakazawa will oversee and manage overall operations as he succeeds Pat Ambuske, who is retiring.

Soave Acquires New Center Stamping

This deal compliments their scrap metal operations, steel services center, retail aftermarket parts and automotive dealerships.