TIG Welders

Filter by Process Zone:

Welding Systems Reduce Costs in High Volume Operations or Jobsite Work

The TPS/i TWIN Push tandem welding system from Fronius is ideal for high-volume precision, while their TransSteel Series multi-process welding systems provide high-quality flexibility do a wide variety of different tasks.

Tackle Different Challenges on the Jobsite With a Welder/Generator

Wasted time and lost productivity are enemies in any welding operation, especially in harsh conditions, on large jobsites or in applications where it’s difficult for operators to get to where the work must be done. The right welder/generator system, equipped with advanced technologies, can help complete work faster while also improving quality and safety.

Miller Announces Giveaway

The company celebrates 90 years in business with the My Miller Milestone giveaway to recognize dedicated welders.

How to Reduce Weld Defects and Improve Productivity

Advanced welding technologies from Miller Electric provide great process flexibility, reduce welder training time, minimize spatter and rework and improve weld quality for manufacturing, fabrication and construction applications.

Articulated Rests for Support and Easy Access of Torches, Electrodes and Grinders

Ready Rest torch, grinder, wrist, and arm rests from Strong Hand Tools increase work efficiency, reduce wrist fatigue, enable freedom of movement, prevent torch damage and more.

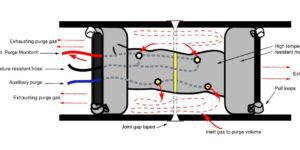

Welding New Nickel Alloy

Inconel 740H and other new superalloys provide major improvements in mechanical properties and corrosion resistance at elevated temperatures, but they still need careful purging during welding in order to preserve these characteristics.

Create A Community for Sharing Metalworking Automation

Using the HKP Mobile App from Haydon Kerk Pittman, technical information and other resources on linear and rotary solutions can be easily shared among colleagues and teams for automation in metalworking, inspection and material handling applications.

What You Need to Know About Weld Anatomy and Joint Geometry

Are you wasting lots of time and money on welds that are larger than they need to be, particularly on thicker materials? Or dealing with inconsistent quality or increased crack sensitivity due to welds with improper dimensions? There are many different ways to design welds that strike the best balance between weld quality and productivity.

Switching Polarity in Welding Applications

When competing for time-critical jobs, saving even a few minutes with each changeover can make a significant difference and reduce operator exposure to trip and fall hazards. Investing in technology that allows welders to easily change processes with the push of a button at the weld joint can save substantial time, increase weld quality and improve operator safety.

Montage Partners Acquires METALfx

The existing management team of METALfx remains and also owns a meaningful equity stake in the business.

Manufacturing vs. Fabrication: How to Make the Distinction

Is your operation highly repeatable or do you require more equipment and personnel flexibility for a wider range of work? Knowing the difference is important in selecting the right equipment and process optimization needed to maximize productivity, save time and money.

How Inexperienced Welders Do More in Light Fabrication

Easily moved around the shop or in the field, the Millermatic 255 MIG welder and Multimatic 255 multi-process welder from Miller Electric are simple to set up and use so that operators of all skill levels can get more done, particularly when welding thin materials.