Toolholders & Adapters

Filter by Process Zone:

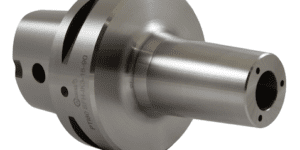

Tool Holder’s Coolant Holes Maximize Coolant Flow

The secret to better tool life is great coolant flow, and AccuKool is the secret behind Accutek’s AccuGrip Shrink Fit tool holder. Its specially designed holes keep coolant flowing to and through cutting flutes.

The One Big Flaw in CNC Milling That’s Costing Tool Life

Early adoption of JM Performance Products’ High Torque retention knobs helped a titanium machining company overcome deficiencies at the spindle to advance its aerospace production trajectory.

Gear-Cutting Shop Hops Hurdles With Tool-Holding Investments

A woman-owned Massachusetts company solved its feed and speed struggles with conventional side-lock and collet holders by turning to HAIMER shrink fit products. Short projection length with the Ultra Short Power Shrink creates more rigidity, and the Power Mini helps operators handle hard-to-reach areas.

Redesigned Insert Clamp Improves Rigidity

The toolholder for Horn USA’s Supermini grooving and boring tools applies a tensioning wedge to the insert’s face rather than circumference, increasing rigidity and repeatability.

Intelligent Toolholder Enables Real-Time Process Control

Equipped with a sensor, battery, and transmitting unit, Schunk’s iTENDO toolholder is a closed-loop data acquisition tool that securely gathers and shares process data that operators can immediately react to.

Why You Should Take Another Look at Shrink-Fit Tooling

An expanding array of design and connectivity options is making this tooling method faster and easier. This cost/benefit analysis shows why shrink fit’s benefits extend beyond mold-making and 5-axis machining applications.

Coating Chemistry Ingenuity Stands Behind Stainless Steel Turning Results

Seco Tools’ Duratomic TM grades has thermal and mechanical properties as well as chrome-colored Used-Edge Detection technology to minimize waste. With new geometries and chipbreakers, three grades are tailored for distinct application demands.

How to Scale Up Fast With Flexible Production Strategies

With the right tools and CAM software, toolmakers and mold makers can keep production capacity flexible and will be able to ramp it up by up to 85% as they restart after the coronavirus outbreak. Hoffmann Group USA’s director of milling explains.

Problem-Free Disc Milling for Tough Metals

Seco’s 335.18 and 335.19 cutters have close-pitch insert pockets to create stability. Meanwhile, a corrosion-resistant cutter body contributes to high performance when milling stainless steel, titanium and superalloys.

High Tech Coolant for General ISO Turning

Seco expands its range of Jetstream tooling holders, offering 182 new products for all inch, metric and Seco-Capto holders. The internal coolant technology extends tool life while shrinking setup and indexing times.

Kitagawa Northtech, Inc., Acquires Tecnara Tooling Systems’ Core Products

Kitagawa NC Rotary Tables and exclusive distribution rights to MST Yellow Angle Head products are included in the deal that took effect April 1. The two companies have enjoyed a successful sales and business relationships for over 25 years.

Perfect Timing: Germ-Free, Hands-Free Door Opener

To help stop the spread of germs and bacteria, Industrial Magnetics has developed the Foot-Pull Door Opener that can be attached to the bottom of a door. The company is donating 100% of the profits from sales of the device to food pantries in its community.