Tooling & Workholding

Filter by Process Zone:

Modular Clamping System Reduces Setup Time, Increases Machine Utilization

The FCS Modular Clamping System (Breyl) from SST uses virtual design during the CAD/CAM stage of part production to project a grid on the workpiece and calculate the best way to attach the part for machining and chip evacuation.

American National Carbide Reaches ERP Milestone

They recently marked 40 years of using ERP software from Global Shop Solutions.

New Director of Business Development at Walter

Thomas Benjamin now directs their business development in North America.

Walter Surface Technologies Appoints New President

Marc-André Aubé is their new president and chief operating officer.

BIG KAISER and Team Penske Form Technical Alliance

Team Penske will now use BIG KAISER technology for machining parts for their Ford Fusions and Mustangs used in NASCAR racing.

Fullerton Tool Joins Jergen in China

Fullerton establishes direct sales and support in the Chinese market through Jergens Shanghai.

Trends in Hydraulic Clamping Systems for the Press Brake

Depending on the press brake and setups, there are a number of hydraulic clamping options that fabricators can use to work within their budgets and production requirements. From a fully modular hydraulic clamping system or by retrofitting safety tangs onto straight-tanged punch tools, streamlining production with hydraulic clamping solutions can deliver greater efficiencies in your shop and help you compete with the world.

Get a Better Grip

Here are some tooling and workholding innovations that can help you increase productivity, improve quality and reduce costs in your machining operations.

Basic Mill End Mills that are Anything but Basic

The Basic Mill from Haimer is ideal for slotting, trochoidal milling, steep ramping and even plunging in stainless steel, alloy steel, cast iron, aluminum and general steels.

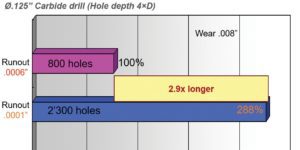

Tools, Holders and Runout: Uncover the Hidden Savings

Runout can be fickle, but finding a solution for it can pay significant dividends. Here are some insights into how much a little wobble can really increase your costs.

Cutting Through the Confusion with Non-Woven Convolute Wheels

The complicated array of convolute wheels being used on the production floor can confuse operators who find it difficult to select the right one for their specific deburring or finishing job. But now a new system simplifies all of that, reducing lost time in selection and downtime due to rework, increasing cost savings through higher productivity.