Tooling & Workholding

Filter by Process Zone:

Wear-Optimization App Helps Decrease Wear Rates and Associated Costs

The app from Walter USA enables users from any mobile device and operating system to identify all specific forms of wear on indexable-insert and round-tool solid carbide applications, from milling, drilling and threading to turning, grooving and parting.

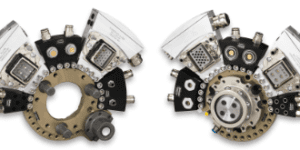

Robotic Tool Change System

Ideal for medium payload range automotive applications, the compact MPS 130 fully automatic tool change system from Stäubli is only 1.8 kg on the robot side and 1.1 kg on the tool side, with a maximum load of 100 kg and a bending moment of 900 Nm.

Automated Tool Change Increases Machine Tool Capability

With a stop block that is custom made for each machine type so that it fits perfectly, the Alberti Leonardo electric spindle from Koma Precision can achieve speeds of 60,000 rpm while maintaining the spindle position and accuracy.

MA Automotive Tool & Die Installs SMIRT DieBuild

They can now integrate detailed manufacturing processes for each die into their CNC programming and design visualization.

Integrated Digital Tooling Portal

Compatible with all mobile and desktop devices, My Pages from Seco Tools provides easy, round-the-clock access and transparency for every user in every part of the machining process, from the operator and programmer to purchasing.

Connecting Tools for The Internet of Things

CoroPlus from Sandvik Coromant is a platform of connected tools and software that can send and/or receive data to reduce data waste and improve manufacturing processes from pre- to post-machining.

Opening a Connected Path from Digital Art to Part to Profit

Having data is not enough. Whether the data is identifying and describing the workpiece, the materials, the machines that will make it, the approval specification or other manufacturing criteria, all of the information must be organized in a manner which allows the data to work for you. This is where the digital intelligence of the smart factory comes into play.

Workholding Collet Changeouts Get Totally Automated

Cutting edge workholding automation technology that incorporates robotic workpiece loading/unloading is creating total machine automation for job shops that opens up wide ranges of application possibilities for ever shorter production runs.

Tool Management

The Smart Factory uses cyber-physical automation for tool management at every stage: from purchasing to programming to operation; from selecting, ordering and maintaining the proper tools for particular jobs to precise recommendations for cutting data to generating CNC programs for specific applications.

Make the Most of a Tool’s Entire ‘Life’

Successful shops always look for ways to differentiate and innovate for competitive advantage. Cashing in on the entirety of a tool’s life with an advanced tool management system is perhaps the most effective way to do that right now.