Tooling & Workholding

Filter by Process Zone:

Advanced Tooling for Punch Press, Press Brake, Laser Cutting Operations

Take a closer look at Ultra QCT Quick Change Tooling, CleanBend Press Brake Tooling, One-Micron Fiber Laser Lenses and more from Mate Precision Tooling.

PFERD Appoints Technical Sales Specialist

Tim Lee is responsible for working with customers on their cutting requirements, particularly large diameter cutoff wheels.

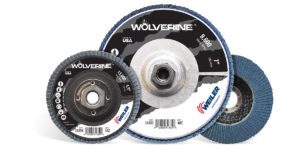

Re-Engineered Abrasive Flap Discs Offer Maximum Cut Rates and Extended Life

Vortec Pro abrasive flap discs from Weiler have been re-engineered under the Wolverine family of discs to deliver exceptional value.

FABTECH 2016 Sneak Preview: Welding

The 2016 edition of FABTECH is on track to be one of the largest metal fabrication events ever at the Las Vegas Convention Center in Las Vegas from November 16-18. This special sneak peek provides technical reviews of some of the equipment, power sources, positioners, systems and accessories that will be exhibited in the Welding Pavilion to help you get a head start on navigating the show floor and managing your time while you’re there.

PFERD Hosts Career Fair

Students and visitors tour their manufacturing facility and learn about various career opportunities within manufacturing.

Metal Finishing Solutions

Files, burs, brushes, grinding and cutting wheels and power tools from PFERD increase operator efficiency, health and safety, and optimize process effectiveness.

Depressed Center Grinding Wheels Remove More Metal Faster with Less Operator Fatigue

For substantially faster grinding, Norton Quantum3 wheels from Saint-Gobain Abrasives remove almost twice the amount of carbon steel at five minute intervals compared to other competitive wheels.

Wireless Communication Control for Head & Tailstock Positioners

The Wireless Communication Control system between head and tail stock from ALM Positioners uses Trusted Wireless 2.0 technology for high reliability, secure transmission and flexible network structures with digital readout display of up to 250 devices.

U.S. Cutting Tool Orders Bounce Back

August cutting tool consumption of $175.2 million jumped 19.2 percent from the previous month.

FABTECH 2016 Sneak Preview: Metalform

The 2016 edition of FABTECH is on track to be one of the largest metal fabrication events ever at the Las Vegas Convention Center in Las Vegas from November 16-18. This special sneak peek provides technical reviews of some of the machinery, tooling, systems and accessories that will be exhibited in the Metalform Pavilion to help you get a head start on navigating the show floor and managing your time while you’re there.

Band Saw Blades for Heavy Duty Cutting

Primalloy Saw Band Saw Blades from Starrett provide superiority in overall wear and operating life without the expense of carbide-tip solutions. It minimizes blade replacement to cut costs for steadier production.

How to Double Throughput on Turning Large Scale Parts

Shops that turn large scale parts for power generation equipment and oil patch machinery are now achieving up to twice the material removal rate and extreme depth of cut, even while cutting forces stay the same as before or actually decrease and insert edge life improves. Here’s how they do it.