Tooling & Workholding

Filter by Process Zone:

Versatile Milling of Small Features on Any Size Medical Component

The versatile CoroMill 390 end mill with size 07 inserts for small diameters from Sandvik Coromant is ideal for shoulder milling, deep shoulder milling, edging, linear and helical ramping, plunge milling, slot milling and face milling.

Solid Carbide End Mills for High-Feed Milling

SN 200R/400R/500R solid carbide end mills with 2-, 4- and 5-flute options from Niagara Cutter allow medical parts manufacturers to achieve maximum productivity when performing face, slot and select plunge milling operations.

Application Specific Thread Whirling Inserts in Less Than Three Weeks

GenSwiss offers quick delivery of Utilis inserts for thread whirling that improves thread surface finish and can be utilized for threads smaller than 12 mm diameter in medical devices.

Thread Whirl Toolholder for Complex Thread Production of Medical Bone Screws

An inexpensive alternative to dedicated thread whirling machines, this toolholder from EXSYS Tool is ideal for processing micro-components and machining high-precision OD threads in challenging materials with long, slender thread profiles.

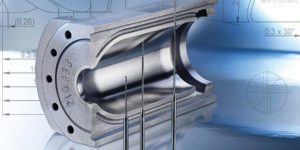

Precision Hydraulic Chucks for Medical Manufacturing

High performance WTE Precision Hydraulic Chucks from ERI America provide extreme temperature stability, super strong holding forces combined with excellent vibration damping and high radial stiffness to guarantee improved surface qualities on the workpiece during machining.

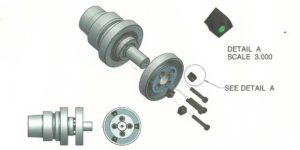

Grinding Wheel Arbor for Producing Shaped Bone Fragments in Surgical Grafting

Briney Tooling Systems developed a custom HSK50E balanceable grinding wheel arbor with a special anti-bacterial/viral chrome plating to meet demanding ISO 13485 requirements for medical OEMs and contract manufacturers.

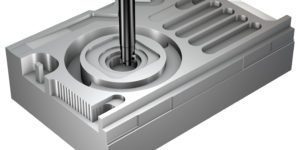

The World’s Smallest and Strongest Clamping System

The extremely thin VERO-S NSE mini pneumatic quick-change module from SCHUNK is ideal for retrofitting and fully utilizing existing machines to directly clamp and process small precision parts used in medical technology.

High Speed Air Power Spindle for Micro-Machining Medical Parts

Driven by air supplied through a stop block or through the machine spindle, the RBX12 Air Power Spindle from BIG KAISER achieves variable rotational speed of 100,000 rpm to 120,000 rpm so that normal machine tools can be upgraded cost effectively to perform micro-machining.

How Close is Close Enough When Trying to Achieve Positioning Accuracy?

Which is better: pneumatic or electric actuation? This review of the various options of each process, along with their advantages and shortcomings depending on application circumstances, can help you make more informed decisions about positioning design and selection.

What You Need to Know Right Now to Improve High-Volume Micro Manufacturing

Opportunities abound for shops to cash in on the ever-growing micro machining market, but the differences between different types of micro tools vary from those found in standard tooling. Here are some insights into the extra care and know-how needed to achieve success and build a successful reputation as a reliable supplier of micro machined parts.

PFERD Appoints New VP Sales

Jon-Michael Raymond now manages their U.S. sales in the welding, industrial and STAFDA sectors.