Tooling & Workholding

Filter by Process Zone:

Complete Machining of Crankshafts in Just One Setup

Automation meets clamping technology in the combination of a shaft chuck, steady rest and gripping technology from Röhm that is ideal for machining and transport of crankshafts in different manufacturing stages.

Advanced Tool Holders and Shrink Fit Technology

The modular Duo-λock interface for carbide cutting tool heads, the Safe-λock tool clamping system, Power Mill end mills and other technologies from Haimer address the machining process from spindle to part.

High Speed Spindles for Milling, Cutting and Grinding

Powerful high speed Micro Line spindles from IBAG fit Swiss turning machines in spindle sizes from 16 mm to 33 mm diameter, speeds to 120,000 rpm and power to 390 watts.

IMTS 2016: Abrasive Machining, Sawing, Finishing

Here are solutions for applications requiring high tolerance and precision surface finish, including grinding technology, sawing and cutoff machines and a variety of finishing systems, such as lapping, balancing, honing and polishing machines. You’ll also find advancements in abrasive size, shape or composite materials, and nano-materials for improved surface finishes in more constrictive areas.

New Geometry Tackles the Toughest Rough Turning Applications

Double-sided ISO indexable inserts with RP7 geometry from Walter combine a ground contact surface with an optimized profile that has a tailored protective chamfer to guard against fracturing.

Top of the Line Finishing on Steel, Stainless Steel

The Topcut sanding disc from Walter Surface Technologies uses a new formulation of blue Zirconium grain blend to remove material 50 percent faster and with a longer lifespan.

Deburring, Edge Blending and Surface Finishing of Hard Materials

Diamond Flex-Hone Tools from Brush Research Manufacturing use resin bond diamond crystals with high friability that creates self-sharpening edges to provide a quick cut-rate and optimal finish.

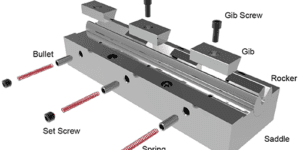

Take Care of Tool Holders, Prevent Cycle Disruption

There are three particularly sensitive areas of the tool holder assembly that can experience process-affecting wear and tear and cause a cycle to change. By identifying and addressing issues early in these areas, you can prevent small tool holding imperfections from turning into bigger problems.

An Ideal Alternative to Wiping Dies

The Posi-Bend self-contained rotary bender from Dayton Lamina cams the material without undesired distortion, sliding, or marring.

Haimer and Mapal Reach Licensing Agreement

Starting in October, Mapal will offer selected cutting tools for high-performance machining with the Safe-Lock shank from Haimer.

Do Lathe Operations on the Bed of Your Mill

RapidTurn from Tormach securely positions parts in 15 deg increments for secondary work on the primary spindle of the mill, which is ideal for cutting wrench flats or drilling cross holes on turned parts without additional setups.