Tooling & Workholding

Filter by Process Zone:

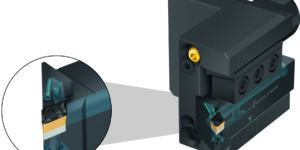

New Turning Tool Holders for Positive Indexable Inserts

New Walter turning tool holders deliver efficiency by precisely directing coolant to exactly where it is needed.

New Orbital Drill/Thread Milling Cutter Reduces Hard Machining Times

The Walter USA solid-carbide orbital drill/thread mill, the TC685 supreme thread milling cutter, is for hard machining of the core hole and thread in one operation.

Enter #ANCATooloftheYear2024 to win a trip to Australia and AUD$10,000

ANCA’s prestigious awards for creative trailblazing toolmakers and talented female machinists provide opportunities to seize global spotlight with outstanding designs and skills.

Pneumatic Swing Clamps for Stronger Clamping Force in Workholding

Air-assisted pneumatic clamps from Fixtureworks offer more efficiency and automation in production and are automated machining clamps with a unique clamping mechanism.

Workholding Devices: Minimize Downtime and Maximize Gripping Power

The enhanced accuracy and rigidity of chucks and collets improves your shop’s overall machine performance.

CERATIZIT’s Sustainability Mission Results in Maximum Productivity

CERATIZIT hosted Open Days 2024 in April where it showcased its sustainability initiatives and various new production facilities, sales and technical centers and much more.

New Helical Milling Cutter with BC System Inserts

Walter USA, LLC unveils the XTRA∙TEC XT M5250, a full-effective helical milling cutter that provides a high level of process reliability and is suitable for full slotting.

Single Point Threading Ensures Strength and Durability of Retention Knobs

TJ Davies forms its retention knob threads using single point threading to Imperial or metric standards, which ensures that the threads are balanced (lead-in/lead-out at 180 degrees) and that full depth is attained for each thread.

Unlocking Manufacturing Excellence: Sandvik Coromant Centers as Advanced Testing Facilities

Navigating new technologies, global crises and the pressure to become more sustainable and productive can place a lot of weight on a manufacturer’s shoulders, and those working in the industry shouldn’t weather the storm alone. Fortunately, tailored processes, developed by seasoned experts, can pave the way for manufacturing success.

Additively Manufactured Milling System Optimizes Coolant Supply

CERATIZIT’s additively manufactured MaxiMill – 211-DC indexable insert milling system with advanced coolant supply was developed for heat-resistant materials such as titanium and other super alloys.

Revolutionizing the World of Machining: the UGIMA-X Martensitic and Duplex Steels

The new UGIMA-X grades from the Swiss Steel Group are characterized by their reproducible behavior during machining, which offer higher productivity and optimal adaptability to the various cutting conditions on automatic and CNC machines.

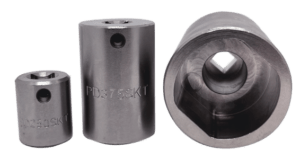

Tooling Tech Group Adds Sockets to its Segen Quick Change System

The sockets are designed to complement the existing series of knobs and cylinders to speed setup in a variety of processes and applications.