Tooling & Workholding

Filter by Process Zone:

New CoroMill® MF80 for high-performance face and shoulder milling

Global metal-cutting leader Sandvik Coromant is expanding its milling offering with the new CoroMill® MF80 for automotive milling applications in ISO K and ISO P materials in close to 90-degree operations with fixture constraints.

Walter Launches the Next-gen of Straight Flute Drills for Aluminum and Cast Iron

The DC165 Advance solid carbide drills have four polished margins that reduce friction and improve hole accuracy, surface finish, roundness, and straightness.

Osborn Testing Innovative, First-of-Its-Kind Stringer Bead Brush

The new bead brush is setting a new standard in the welding, pipeline and metal fabrication markets.

New Versatile Range of Solid End Mills

The CoroMill® Dura offers flexible roughing and finishing in multiple materials

Sandvik Coromant Helps Electric Vehicle Manufacturers Compete

Power skiving is the fastest-growing method of gear machining. The process combines shaping and hobbing into a single, continuous cutting process.

Flying S Inc. Improves Accuracy and Reduces Retention Knob Failures

Company utilizes JM Performance Products’ High Torque retention knobs, which eliminate the toolholder expansion responsible for costly CNC milling and boring issues.

Cutting Tool Manufacturers find Opportunity in the Deep-hole Drilling Market

Understanding the application and being aware of common challenges can help make a difficult operation both productive and profitable.

Non-woven Abrasives Optimize Finishing while Reducing Grinding Steps, Increasing Productivity

Modern abrasive grains and stronger bonding methods found in the latest non-woven abrasives enable shops to quickly achieve desired surface quality.

New Tool-changing Options Deliver Accuracy and Safety for Users

Versatile and robust robotic tool-changing applications optimize your shop’s processes.

Time to take the Blinders off When it Comes to Tooling Up

As technology continues to advance on the machine side, tooling and workholding offer new and different opportunities to bolster an operation.

Sneak Preview: FABTECH 2022

At FABTECH, the metal fabrication industry can tap into the power of this in-person event to discover new innovations and become inspired.

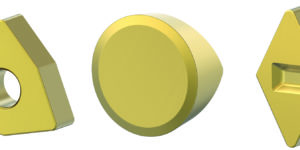

Higher wear resistance and longer tool life in hard turning applications up to 58 HRC with Kennametal’s KYHK15B™ grade

New ceramic grade delivers highest productivity when

machining hardened steels, high-temperature alloys, and cast

irons.