Tooling & Workholding

Filter by Process Zone:

Manufacturing Process Enhances Cutting Wheel Durability

Weldcote’s A-Prime Plus line of cutting wheels lasts longer because they’re manufactured via a multistep granulation process that evenly distributes each individually coated aluminum oxide grain.

Seamless Finishing Wheels for Fine-Tolerance Work

Shur-Brite finishing wheels from Superior Abrasives produce a satin finish without the visible transition lines often caused by traditional flap brushes. Their seamless design ensures conformability by providing superior cushioning at low speeds.

Burnishing Tools for Virtually Any Production Need

Sugino’s Superoll burnishing tools provide 0.1-to-0.8-micron finishing in one pass. They integrate into machining centers to improve productivity by eliminating secondary processes, such as grinding and honing, without removing additional material.

Reformulated Grinding Wheel Lasts Almost 50% Longer

The entire working section of Rex-Cut Abrasives’ Aluminator grinding wheel can be used without sacrificing productivity or finish. Its cotton fiber breaks down to continually expose new grit, providing consistent metal removal for the wheel’s entire life.

Mounted Stone Kit for Cooler Cutting

The distinctive pink abrasive grain makes Palmgren’s mounted stones exceptionally durable while providing cooler cutting.

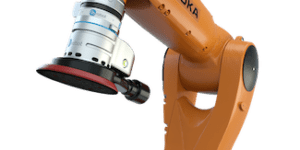

Robotic Kit for Precise, Affordable Finishing

OnRobot’s random orbital sander is an out-of-the-box automated sanding and polishing solution that works with virtually any collaborative robot (cobot) brand. Brushless electric motor costs less than traditional pneumatically powered sanding systems.

Reusable Grinding Wheel

The core of Norton Winter Aeon electroplated grinding wheels from Saint-Gobain Abrasives can be re-plated with new diamond or cBN grain in a continuous re-plating cycle for increased efficiency and long life.

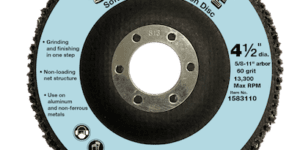

Flap Discs Grind and Finish Aluminum In One Step

Lawson Products’ nonloading Blue-Kote flap disc incorporates aluminum oxide grain for excellent grinding and smooth, scratch-free finishing. The long-lasting disc reduces costs by saving process time and eliminating the need for product changeover.

Belt Grinder with Easy-to-Reposition Head

All an operator needs to change the grinding head on the BG448 from Kalamazoo Industries from vertical to horizontal (or any position between) is an Allen wrench. Insert wrench in holes on the contact wheel, loosen the socket head cap screws slightly, tilt head, and re-secure.

Defined Chamfering Deburrs Gear Teeth In Seconds

To enable high-volume gear production, Horn USA will develop a carbide milling tool and machining program to produce defined chamfers based on material and gear tooth geometry. The service quickly pays for itself and doesn’t require special workholding.

Single-Piece Hub Design Lengthens Sanding Tool Life

Dynabrade’s replacement pads fit the company’s Dynorbital Extreme and Dynorbital-Spirit random orbital sanders as well as most competitive brands. Co-branding and private label opportunities are available.

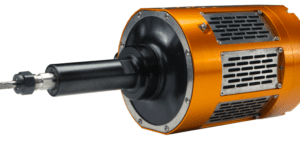

Material-Removal Kit for Demanding Robotic Applications

ATI Industrial Automation’s electric RCE-710 has built-in radial compliance with single-axis lockout to facilitate robot programming. Available as a complete end-effector package, the robust tool handles a wide range of material-removal tasks.