Tooling & Workholding

Filter by Process Zone:

Configure the Ultimate Welding Cell

Mix and match Flexturs welding tables, Gridlok mount systems, and fixture accessories as needed to increase efficiency by eliminating costly and time-consuming jigs. The wheeled workstations are quickly and easily reconfigured and relocated as needed.

Improve Band Sawing Operations with These Solutions to Three Common Challenges

Impediments to fully optimized band sawing can be broken into three broad categories: teeth problems, blade problems, and cutting problems. These troubleshooting tips will help operators of all experience levels work as efficiently as possible.

Fully Automated Tool Presetting Slashes Machining Setup Times

For shops that use shrink fit holders, duplicate assemblies or multispindle machines, Haimer’s VIO linear toolshrink provides fully automated presetting with incorporated shrink fit technology for precise length adjustment on the μm scale that can reduce setup times up to 70%.

Indexable Insert Drill Balances Performance and Cost-Effectiveness

The balanced four-insert design of Walter’s D4120 helps deliver process reliability, enhanced surface finishes, and hole tolerances. Balancing cutting forces between the center and peripheral insert ensures hole-diameter precision.

Increase Productivity When Machining Heat-Resistant Super Alloys

Unpredictable tool life and slow rough-machining speeds hinder heat-resistant super alloy (HRSA) component productivity. New Secomax CW100 silicon carbide whisker-reinforced ceramic insert formats and geometries successfully tackle materials such as Inconel 718 and Hastelloy.

Inserts Support Both Unmanned Production and Custom Components

Sandvik Coromant uses a second-generation chemical vapor deposition (CVD) alumina coating to produce two turning grades – GC4415 and GC4425 – that withstand the extreme temperatures of P25 cutting zones during continuous operations.

12,000 Round Solid Carbide Tools

CNC Software partners with Kyocera SGS Precision Tools to add 10 tool libraries to Mastercam CAD/CAM software. Products include ferrous and non-ferrous cutting tools ranging from end mills, routers, micro tools, and drills to reamers and countersinks.

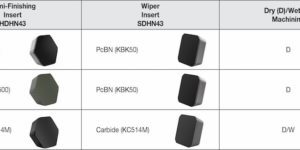

Face Mill for Multiple Cast Iron Applications

Kennametal’s KCFM 45 is a flexible, cost-effective, and user-friendly face mill for gray cast iron, CGI applications, semi-finishing and fine-finishing operations on any type of CNC machining center. Produces surface finishes of 0.8µm Ra (32 µin.) or better, and waviness lower than 10µm Wt (400 µin.).

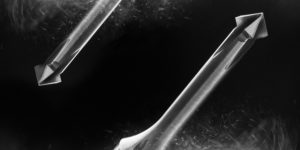

Deep Hole Drill Optimized for Machining Steel

Hoffmann Group’s Garant Master Steel Deep for deep hole drilling improves process reliability at higher cutting speeds. A design that reduces cutting forces and drill guidance that reduces vibration greatly improves hole quality in various machining applications.

All-in-One Tool Cuts Machining Time by 25%

Ceratizit’s FreeTurn tools enhance milling machine productivity by combining multiple-propertied inserts with variable approach angles. The spindle rotates the cutting surface 360 degrees to perform roughing, finishing, contour turning, facing, and longitudinal turning with one tool.

Time-Saving Dual-Purpose Milling Cutter

Big Kaiser’s Noventa from Sphinx is ideal for 90-degree front and back chamfering, and deburring holes up to 4xD. The milling cutter’s design also delivers a surface that feels like a finished product that’s safe to handle.

Clamp Virtually Any Workpiece Geometry

SMW Autoblok’s versatile four-in-one Centco4 2+2 self-centering and compensating chuck minimizes downtime by reducing changeouts and minimizes waste by reducing part deformation.