Tooling & Workholding

Filter by Process Zone:

Yes, You CAN Micromachine With A Standard Machine Tool

In a time when finding new revenue is critical, making capital equipment more versatile can help business. There are few opportunities to affordably expand your shop’s capabilities than to start micromachining with the help of the right tools and accessories.

Six Ways to Improve Grinding Operations

Whether the application is construction, shipbuilding, or general metal fabrication, using the right wheel combined with the proper technique and pressure can eliminate many issues operators face when grinding — saving time and money.

Replacement Sanding Pads Cut Down on Vibration

Dynabrade’s line of random orbital sanding pads are designed as a single piece, which creates a smooth, efficient sanding experience. They also fit most competitors’ sanders.

Mate’s Name Change Points To Entry Into Machining

Under its new corporate name, Mate Precision Technologies looks toward expansion into precision machining. Watch for a major new product release arriving in 2021.

Two High-Speed Solid Carbide Milling Cutters

The MC025 Advance and MD025 Supreme cutters from Walter feature high cutting speeds, exceptional reliability, and universal applicability.

Updated Design, Simulation, and Manufacturing Software

With Solid Edge 2021, Siemens furthers expands the functionality of its product development software suite. Enhancements include new tools for cloud-based collaboration.

Double Turbo Square Shoulder Mills and Inserts

Improve roughing operations and achieve superior surface finishes without high machine power consumption with Seco Tools’ Double Turbo line of cutters. Double-sided inserts and superior milling grades significantly lower finishing cycle times.

Rough and Finish with One Tool

Sandvik Coromant’s M5C90 milling cutter resolves the challenges of machining lightweight aluminium by roughing and finishing in one pass cylinder heads, cylinder blocks, and other automotive components formerly made from heavier cast iron alloys.

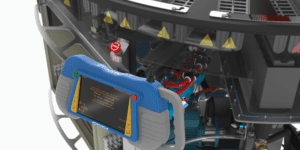

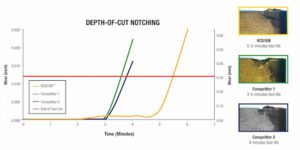

High-Temperature Applications Don’t Faze This Insert

Armed with a special coating and proprietary sputtering technology, Kennametal’s KCS10B overcomes the most common challenges of machining superalloys — cratering and depth-of-cut notching — that often cause unexpected and even catastrophic tool failure.

Full Speed Ahead For Every Milling Job

Hoffmann Group expands its family of high-feed-rate milling tools with the Garant Power Q Double all-round system. Three-part cutting edge increases reliability and productivity by reducing cutting forces and optimizing chip evacuation.

Easy-Index Cutter Heads with Contact Grip

The dual-contact grip of Big Kaiser’s fullcut mill contact grip is a threaded coupling system that achieves machining capacity close to that of integrated types. The taper and flange face make close contact for solid connection, and one holder allows selection from multiple heads.